CNC VMC (Computer Numerical Control Vertical Machining Center) machines are widely utilized in the manufacturing industry for precise machining operations. These machines are equipped with computer-based controls that automate the movement of cutting tools to shape materials like metal, plastic, and wood according to predetermined designs. VMC machines are essentially vertical milling machines with CNC capability, offering enhanced accuracy, efficiency, and versatility in the manufacturing process.

A CNC (Computer Numerical Control) VMC (Vertical Machining Center) simulator is a powerful tool used for training purposes in the manufacturing industry. The full form of CNC machine is Computer Numerical Control machine, which is essential in modern production processes for its precision and efficiency. There are different types of CNC machines, including milling machines, lathes, routers, grinders, and more, each specialized for specific applications. CNC machines work by following pre-programmed instructions to control the movement of tools and equipment, resulting in accurate and consistent production of parts and components. Having a deep understanding of CNC machine working is crucial for operators and technicians to optimize its performance and ensure quality output.

Which is better, a CNC or VMC machine?

When it comes to choosing between a CNC and VMC machine, it largely depends on the specific requirements of the machining tasks at hand. While CNC machines encompass a broader category that includes various types of machines like CNC milling and lathe machines, VMC machines are specialized vertical machining centers specifically designed for vertical operations. VMC machines are preferred for tasks that involve cutting, drilling, and shaping materials vertically with precision and efficiency.

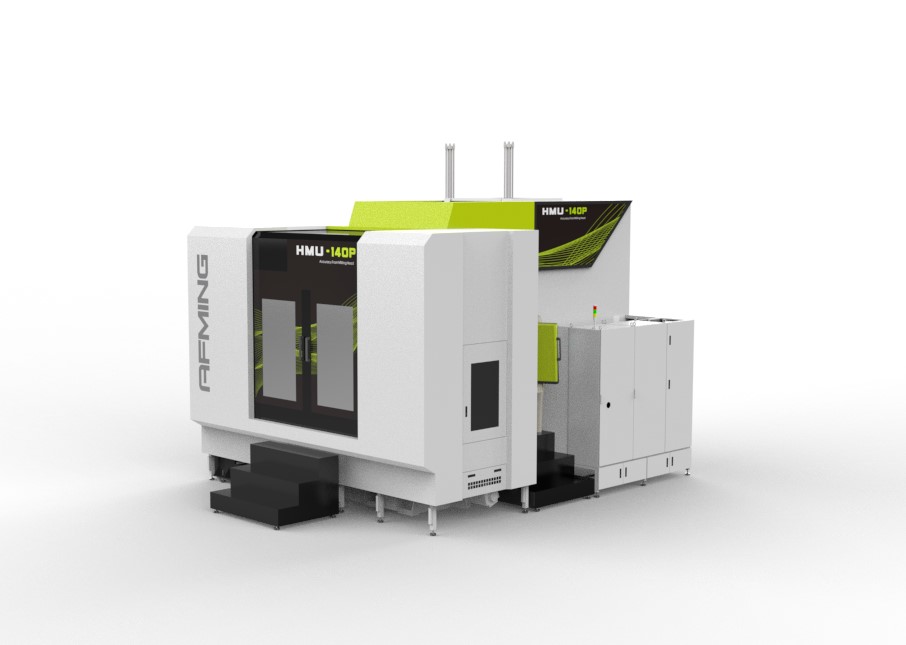

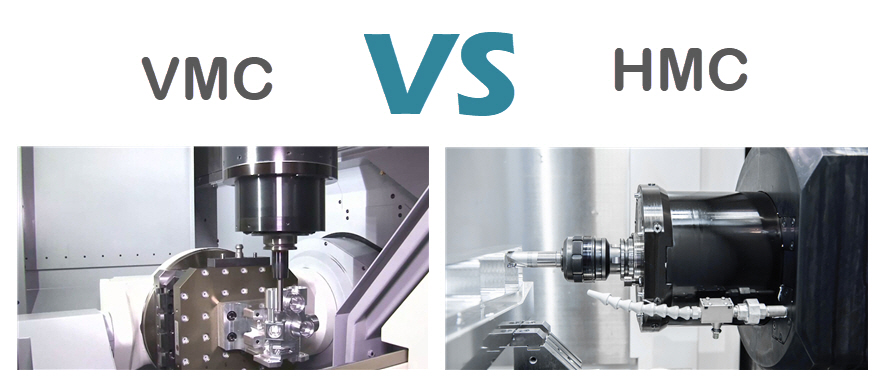

What is the difference between a VMC and a HMC machine?

The main difference between a VMC (Vertical Machining Center) and an HMC (Horizontal Machining Center) lies in the orientation of the spindle. VMC machines have a vertical spindle that operates perpendicular to the work surface, enabling vertical machining operations. On the other hand, HMC machines have a horizontal spindle that operates parallel to the work surface, making them suitable for horizontal machining tasks. While VMC machines are ideal for tasks requiring deep cuts and intricate designs, HMC machines are more suitable for tasks that involve larger workpieces and high-volume production.

What is CMC and VMC?

CMC (Computerized Numerical Control) and VMC (Vertical Machining Center) are both technologies used in the field of CNC machining. While CMC refers to the computerized control system that automates machining processes, VMC specifically denotes a type of machine tool that performs vertical machining operations with the help of a computerized control system. These technologies play a crucial role in enhancing precision, productivity, and repeatability in the manufacturing industry.

CNC Machine Price

The price of a CNC machine can vary significantly depending on factors such as size, complexity, brand, and technological features. Entry-level CNC machines like desktop CNC mills can cost a few thousand dollars, while high-end industrial CNC machines can range from tens of thousands to several million dollars. It is essential to consider factors like performance, durability, and after-sales service when evaluating the cost-effectiveness of a CNC machine for your specific machining needs.

CNC 5 Axis Machine

CNC 5 axis machines are a type of CNC machine tool utilized for precise cutting and shaping of materials using rotary cutting tools. These machines are equipped with computer-controlled systems that guide the movement of the cutting tools in multiple axes to create intricate designs and prototypes. CNC 5 axis machines are widely used in various industries, including aerospace, automotive, and electronics, due to their versatility, accuracy, and efficiency in producing complex parts.

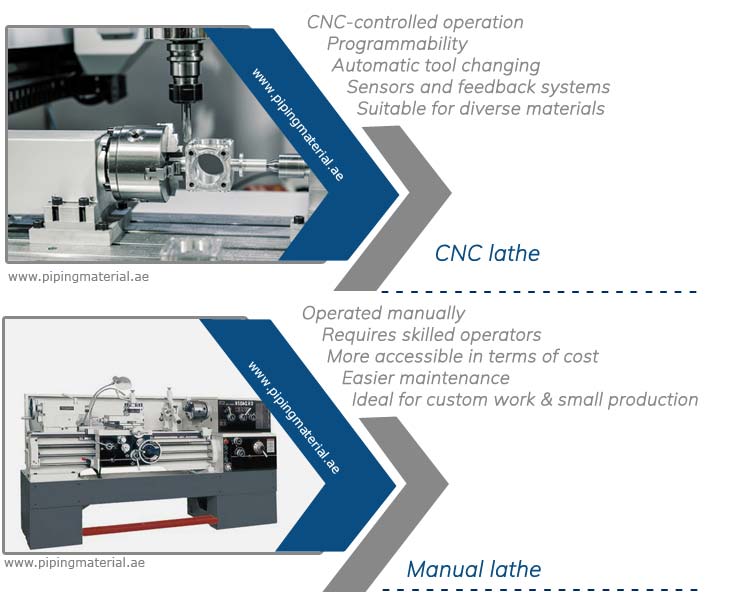

CNC Lathe Machine

CNC lathe machines are another essential type of CNC machine tool used for turning and shaping cylindrical workpieces. These machines are equipped with computerized controls that automate the rotation of the workpiece and movement of cutting tools to create symmetrical parts with precision. CNC lathe machines are commonly used in industries like manufacturing, metalworking, and prototyping for producing components like shafts, bolts, and fittings efficiently and accurately.

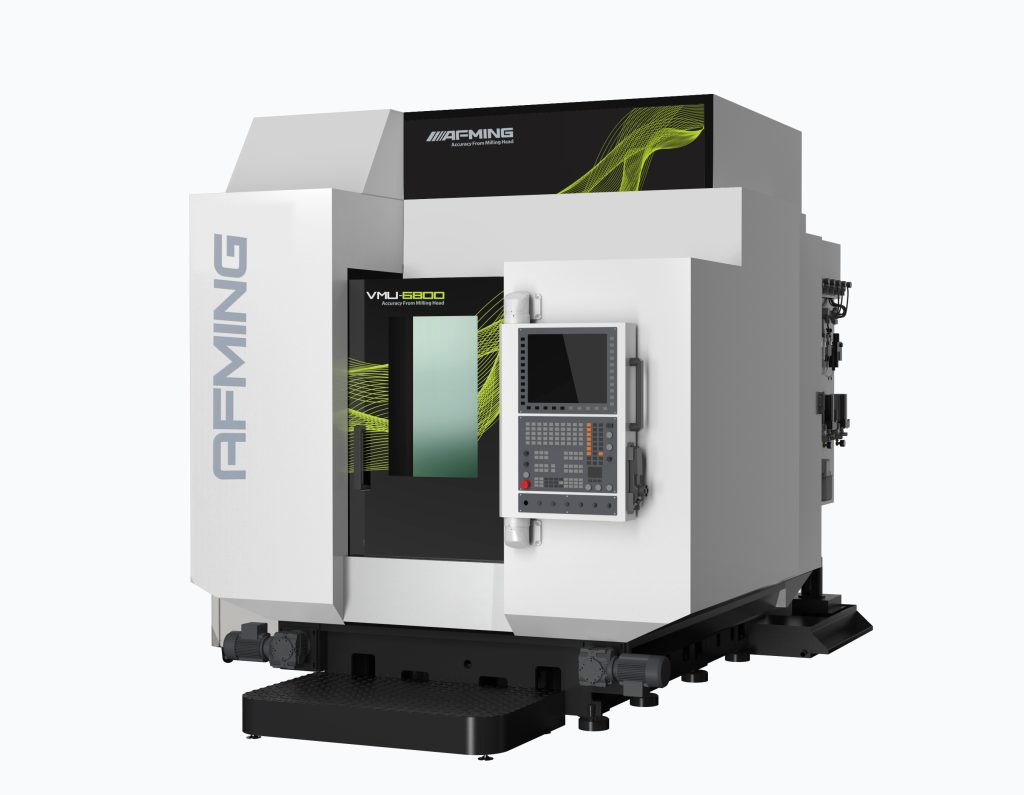

VMC Machine

VMC machines, as discussed earlier, are vertical machining centers that combine the capabilities of a vertical machine with CNC technology. These machines excel in performing vertical machining operations with high precision and speed, making them ideal for producing intricate components and molds in industries like aerospace, automotive, and tooling. VMC machines offer manufacturers the flexibility to achieve complex designs, tight tolerances, and rapid production rates, making them an indispensable tool in modern machining operations.

In conclusion

CNC VMC machines represent a significant advancement in the field of manufacturing, offering unparalleled precision, efficiency, and versatility in machining operations. Whether you require intricate milling, turning, or shaping tasks, these machines provide the technological capabilities to meet your specific production needs effectively. By understanding the differences and advantages of CNC, VMC, and other machining technologies, manufacturers can make informed decisions to optimize their production processes and achieve superior quality results.