5-axis simultaneous machining technology refers to the capability of a machine tool to control at least five coordinate axes (three linear axes and two rotational axes) that can move in a coordinated, simultaneous motion under the control of a Computer Numerical Control (CNC) system during machining. This technology enables multi-surface machining of workpieces and is particularly suitable for manufacturing complex surfaces and high-precision parts.

5-axis simultaneous machining exhibit the following characteristics

High Efficiency and High Precision: Multiple surfaces of a workpiece can be machined in a single setup, reducing setup times and improving machining accuracy.

Adaptability to Complex Surface Machining: Capable of high-precision machining of complex spatial surfaces, suitable for modern molds, automotive components, aircraft structural parts, etc.

Flexible Spindle and Table Design: The spindle can rotate around the X-axis or Z-axis. Through the combination of the A-axis and C-axis, inclined surfaces, angled holes, etc., can be machined, enhancing machining flexibility.

Reduced Need for Special Tooling and Fixtures: Using 5-axis technology reduces reliance on special cutting tools and fixtures, lowering costs.

Extended Tool Life: By optimizing tool paths, the effective cutting edge length of tools can be increased, cutting forces can be reduced, and tool life can be extended.

5-axis Machining Centers Classification

5-axis machine tools are primarily classified into the following two basic types based on the configuration of the rotational axes and structural layout, with various specialized structural forms derived from them.

Classification by Rotational Axis Configuration

| Type | Rotational Axis Configuration | Typical Applications | Structural Characteristics | Limitations |

| Double Rotary Table | Both rotational axes (A/C or B/C) integrated into the work table | Small precision parts, impellers, precision molds | Fixed spindle, high rigidity, high machining efficiency | Limited table load capacity and size |

| Double Swivel Head | Both rotational axes (A/B or A/C) integrated into the spindle head | Large complex surfaces, aircraft fuselages, large molds | Flexible spindle, complex structure, higher table load capacity | High demands on spindle dynamic performance, higher cost |

| One Swivel Head + One Rotary Table | Spindle swivel head + rotary work table | Medium-sized parts with compound angles, engine blocks, irregular parts | Balances rigidity and flexibility | Tool length directly affects swing arm length; error increases with tool length |

Classification by Spindle Structure

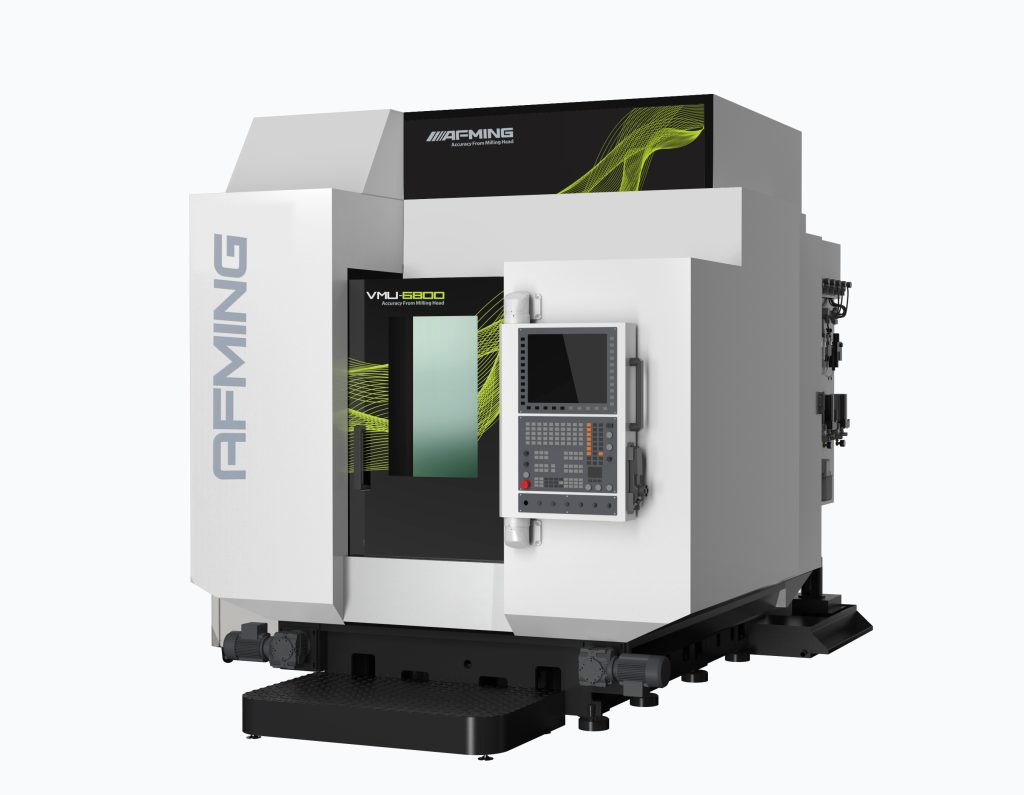

5-Axis VMC: The defining feature of five-axis vertical machining is a vertically oriented spindle. The workpiece is positioned on a horizontal worktable. This configuration is closest to conventional three-axis machines. Rotary axes are typically integrated into the worktable. Its key advantage lies in machining complex contoured parts, such as impellers and molds. However, workpiece weight limitations on the rotary axes must be considered.

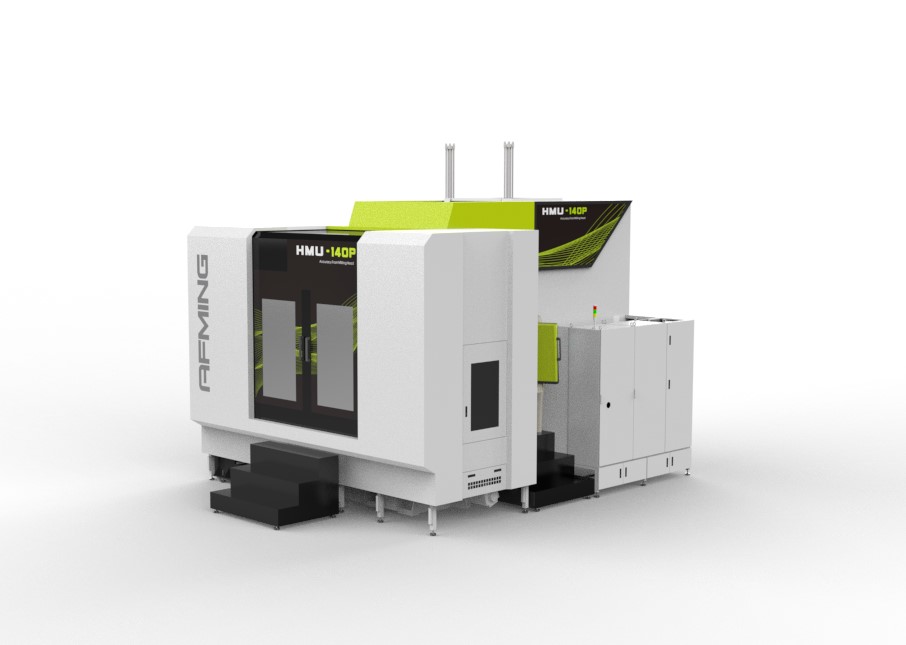

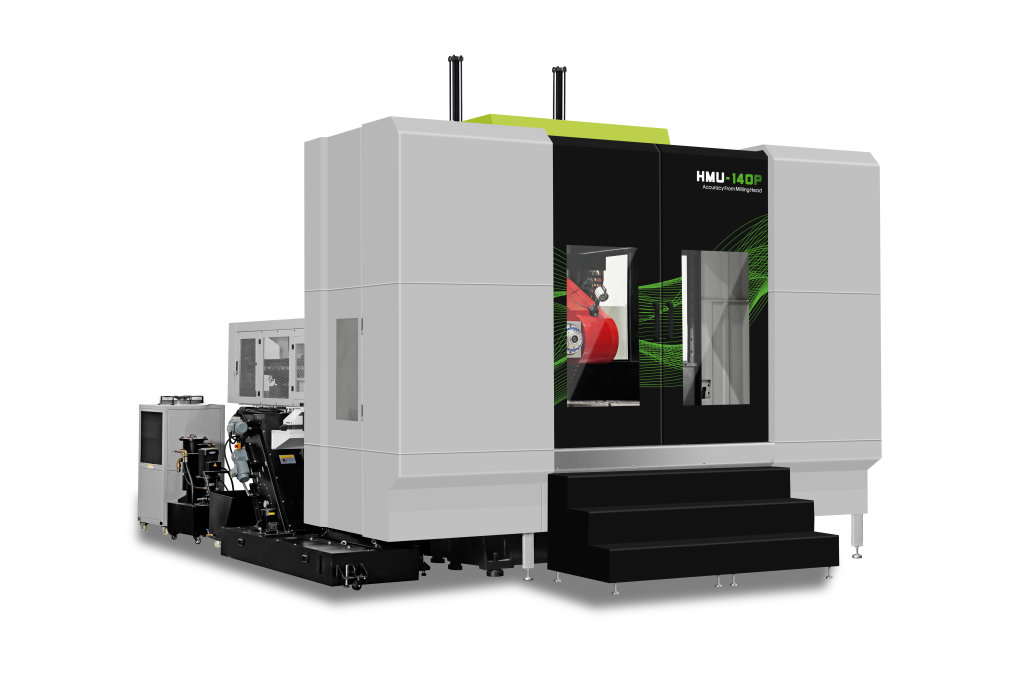

5-Axis HMC: Five-axis horizontal machining centers feature a horizontally oriented spindle. Rotary axes may be incorporated into either the worktable or the spindle head to rotate the workpiece. This structure is particularly well-suited for machining prismatic parts (like engine blocks) because it enables gravity-assisted chip evacuation, preventing chip accumulation in the machining zone. It is commonly used for multi-face machining of workpieces such as automotive engine blocks.

5-Axis Gantry: These machines employ a gantry frame structure, where movement along the Y-axis is typically provided by the traversing cross-rail. This design is especially suitable for machining large-scale workpieces, such as wind turbine components and aerospace structural components. The gantry structure provides high rigidity and stability, ensuring machining accuracy for large parts and offering the characteristics of exceptional rigidity and stability.

Special Structure Types

Vertical-Downward Swivel Head Type: Two rotational axes near the tool tip, but rotational axes not perpendicular to linear axes; head moves vertically downward. Used for machining complex surfaces, e.g., medical devices and precision components.

Vertical-Downward Table Type: Rotational axes on the work table, but rotational axes not perpendicular to linear axes; table can tilt downwards. Facilitates machining of specific workpieces, e.g., small precision parts, mechanical components, molds, and special-shaped workpieces.

Turn-Mill Complex 5-Axis: Integrates turning and milling functions, enabling multi-process completion in a single setup.

Parallel Kinematic (PKM) 5-Axis Machine: Utilizes a Stewart platform structure, offering high dynamic performance, suitable for high-speed light cutting.

How to Distinguish True 5-Axis from Pseudo 5-Axis?

The key difference between True 5-Axis and Pseudo 5-Axis lies in the presence of RTCP functionality. RTCP stands for “Rotational Tool Center Point” functionality, commonly referred to as Tool Center Point Control. It automatically calculates compensation based on the spindle pivot length (for swivel head machines) or workpiece offset (for rotary table machines), making programming simpler and more efficient.

Structural Form and Simultaneous Capability Comparison

| Item | True 5-Axis | Pseudo 5-Axis |

| Simultaneous Capability | 5-axis simultaneous machining (5 axes move coordinated simultaneously) | Mostly “3+2” mode (two rotational axes only position, three linear axes interpolate) |

| Typical Structure | Double Swivel Head, Double Rotary Table, One Swivel Head + One Rotary Table | Commonly retrofitted 3-axis machines with indexing tables |

| Indexing Capability | Supports indexing at any angle | Double rotary table structures can position; swivel head types cannot machine downwards without multi-axis coordination |

Application Performance Comparison

| Item | True 5-Axis | Pseudo 5-Axis |

| Machining Accuracy | High (automatic compensation for non-linear errors) | Low (relies on manual compensation, error accumulation) |

| Programming Flexibility | Supports manual programming, simpler post-processing | Requires specialized post-processors; tool/ machine change needs re-programming |

| Setup Efficiency | Single setup, multi-surface machining | Repeated alignment, low efficiency |

| Cost | High (complex system, core technology monopolized) | Low (mostly retrofitted 3-axis machines) |

How much 5-Axis Machines?

The price of 5-axis machines is significantly influenced by machine type, configuration, brand, and level of domestic production, resulting in a very wide price range.

| Price Range (USD) | Typical Configuration | Target Applications |

| < 70K $ | Retrofitted Pseudo 5-Axis | Light-duty machining |

| 70K $ — 200K $ | Standard Domestic True 5-Axis | Molds, Automotive Components |

| 200K $ — 700K $ | High-End Domestic / Top International Brand Base Models | Aerospace, Medical Implants |

| > 700K $ | Top International Brand Complex 5-Axis | Energy Equipment, Military Precision Parts |

Conclusion

In summary, 5-axis simultaneous machining technology is a key technology in modern manufacturing, significantly enhancing machining efficiency and product quality. With its high technological content and precision machining capabilities, it is widely applied in numerous fields such as aviation, aerospace, military, precision machinery, and medical equipment, playing a crucial role in the development of these industries.