What are the parts of the milling machine?

Milling machines are essential equipment in the manufacturing and metalworking industries, but understanding their components is crucial for proficiency. The primary parts of a milling machine include the base, column, knee, saddle, table, spindle, and overarm. These parts work cohesively to facilitate the milling process, making it imperative for operators to comprehend their functions comprehensively.

What are the 7 major parts of a CNC machine?

CNC (Computer Numerical Control) machines are instrumental in modern manufacturing, enabling precise and efficient production processes. The seven essential parts of a CNC machine are the control panel, machine tool, axis, fixture, spindle, coolant system, and table. Harnessing the potential of these components is vital for maximizing the capabilities of CNC machines in milling and fabrication tasks.

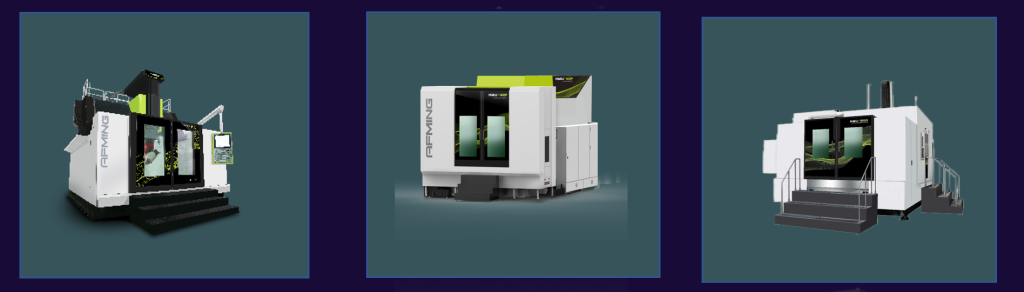

What are the three basic types of milling machines?

Milling machines come in three fundamental variations: vertical, universal, and horizontal. Each type boasts unique features and applications, making it crucial for manufacturers to understand their distinctions to select the most suitable option for their specific needs. By leveraging the capabilities of these diverse milling machines, operators can optimize their production processes and achieve superior results.

What is the function of a milling machine?

Milling machines play a pivotal role in shaping, cutting, and transforming various materials such as metal, wood, and composite substances. The primary function of a milling machine is to remove unwanted material from a workpiece, thus sculpting it into the desired shape and form. Whether it’s for creating intricate components or large-scale fabrication, milling machines are indispensable tools for a wide array of industrial applications.

Vertical milling machine parts – What makes the vertical milling machine components essential for precision engineering?

Vertical milling machines are renowned for their ability to execute intricate tasks with exceptional precision. The critical components of a vertical milling machine include the spindle, knee, quill, and table feed. Understanding the significance of these parts is vital for harnessing the full potential of vertical milling machines in precision engineering and intricate fabrication processes.

Universal milling machine parts – How do the components of a universal milling machine contribute to its versatility?

Universal milling machines are celebrated for their versatility, as they can execute a wide range of milling operations. The crucial components of a universal milling machine comprise the table, saddle, overhanging arm, and cutter head. Recognizing the role of these components is pivotal for maximizing the adaptability and efficacy of universal milling machines across diverse manufacturing tasks and applications.

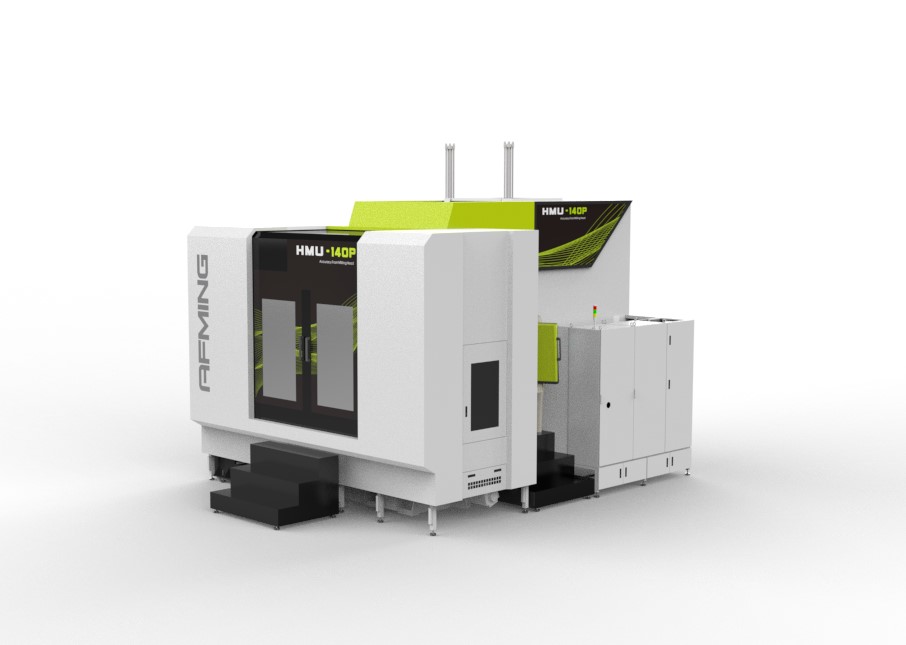

Horizontal milling machine parts – What key elements drive the efficiency of horizontal milling machines in large-scale production?

Horizontal milling machines are favored for their proficiency in large-scale production and mass manufacturing. The essential parts of a horizontal milling machine encompass the arbor, column, overarm, and table. Appreciating the significance of these components is essential for optimizing the efficiency and output of horizontal milling machines in the context of industrial-scale production and manufacturing processes.

By comprehensively understanding the essential components and functions of milling machines, operators and manufacturers can elevate their proficiency and output, ultimately driving enhanced productivity and superior quality in their manufacturing endeavors.