Why Can the Same Machine Model Have Different Production Efficiency?

In the machining industry, many companies find that the same CNC five-axis machine tools can have significantly different production efficiencies.

The reason often lies not with the machine itself, but with the “fixture” – improper fixture selection can not only affect machining accuracy but also lead to wasted man-hours, frequent changeovers, and even uneven equipment load, thereby significantly reducing production efficiency.

Selecting the appropriate type of fixture is a crucial step in improving CNC machine processing efficiency.

Correct Fixture Selection is the Foundation of Efficient Machining

Mechanical processing is generally divided into two categories based on production batch size:

- Small Batch Production: Single pieces, multiple varieties, small batches (accounting for about 70~80% of the total output value of mechanical processing);

- Mass Production: Few varieties, large batch production.

Different production modes have completely different requirements for fixtures. If the selection can be reasonably made according to production characteristics, it can effectively shorten setup time, improve machining accuracy, and reduce labor costs.

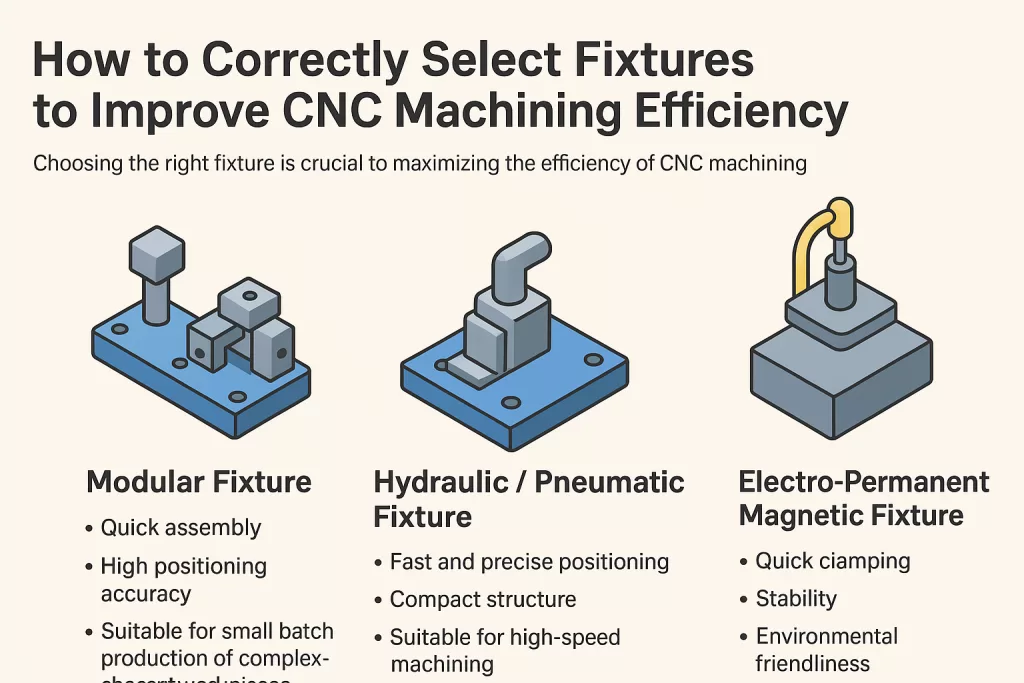

Comparison and Application Scenarios of Three Five-axis Fixtures Types

1. Modular Fixture

Modular fixtures, also known as “building block fixtures,” consist of a series of standardized, multi-functional fixture elements. Users can quickly assemble them according to processing needs, much like building blocks.

Advantages:

- Rapid assembly, shortens production preparation cycle;

- High positioning accuracy, flexible clamping;

- Reusable, energy-saving and low cost;

Applicable Scenarios:

Flexible manufacturing in small batch, multi-variety production environments, such as mold and precision part sample machining.

2. Hydraulic / Pneumatic Fixture

Hydraulic or pneumatic fixtures use oil pressure or air pressure as the power source, achieving workpiece positioning, support, and clamping through a system of components.

Advantages:

- Fast, precise positioning, improves machining accuracy;

- Quick clamping and release, saves clamping time;

- Compact structure, suitable for multi-station simultaneous machining;

- Supports automated control, suitable for high-speed heavy cutting.

Applicable Scenarios:

Suitable for mass production environments such as CNC machine tools, machining centers, and flexible production lines.

3. Electro-Permanent Magnetic Fixture

Electro-permanent magnetic fixtures combine electromagnetic and permanent magnet technologies, offering safety, efficiency, and energy-saving characteristics.

Advantages:

- Fast clamping, stable and reliable holding;

- Supports multi-station, multi-face machining;

- Energy-efficient, environmentally friendly, easy to automate;

- Multiple faces can be machined in a single setup, significantly reducing clamping time.

Applicable Scenarios:

Whether for small batch or mass production, electro-permanent magnetic fixtures can effectively improve machine utilization and overall production efficiency, especially suitable for five-axis machine tools and high-end machining centers.

Using Fixtures Rationally to Unlock Equipment Potential

Rational selection and use of fixtures allow the full potential of CNC equipment to be realized.

For example, for five-axis simultaneous machining centers, using high-precision electro-permanent magnetic fixtures can not only reduce the number of changeovers but also improve machining stability and surface quality, achieving truly “efficient, high-precision, high-quality” production.

AFMing – Providing Systematic Solutions for Efficient Machining

Dongguan AFMing CNC Equipment Technology Co., Ltd. is a professional CNC five-axis machine tool manufacturer integrating R&D, production, sales, and service. The company covers an area of 15,000 square meters, with an annual sales volume exceeding 400 units.

Leveraging its self-developed high-precision five-axis machine tools and supporting fixture solutions, AFMing provides customers with integrated support from machine selection and fixture customization to machining optimization and after-sales service, helping manufacturing enterprises significantly enhance production efficiency and competitiveness.