Top 8 five-axis machine tool manufacturers in China

China 5-axis machine tools market size exceeded the 10 billion RMB mark for the first time in 2024, reaching 10.35 billion RMB. Over the past five years, the five-axis machine tool market size has grown at a CAGR of more than 10%. According to the latest data from MIR DATABANK, China’s five-axis machine tool manufacturers TOP 8 rankings in 2024 are: Jingdiao, TOPNC, KEDE CNC, Haitian Precision, CATO CNC, Himile, Yiteli Technology, and AFMING.

Jingdiao

Beijing Jingdiao is a benchmark enterprise in the field of high-precision CNC machine tools in China. Mainly focusing on precision engraving machines, high-speed machining centers and supporting CAD/CAM software systems, and its equipments are famous for their “micron-level machining accuracy”. Through self-developed CNC system, it realizes ultra-precision control of complex curved surfaces and miniature parts. And it especially occupies a technological high ground in the processing of metal shells in the 3C electronics industry. Its equipment is widely used in high-end manufacturing scenarios such as smartphone structural parts and artificial joint precision molds.

TOPNC

TOPNC focuses on the development and manufacture of five-axis linked machining centers and large gantry machines. It has significant advantages in the field of aerospace complex structural parts machining. Its equipment is known for its high rigidity bed design and dynamic accuracy compensation technology, capable of stable processing of titanium alloys, high-temperature alloys and other difficult-to-cut materials. So it can meet the high efficiency of the aircraft wing beams, engine magazines and other key components needs. TOPNC has achieved breakthroughs in the overall machining technology of large structural components. And its products have been extended to heavy equipment manufacturing fields such as ship propellers and main pump casings of nuclear power plants. It becomes an important promoter of the localization of high-end equipment.

KEDE CNC

KEDE CNC is one of the very few Chinese five-axis machine tool manufacturers have realized the full independent research and development of CNC system, servo drive to the machine tool body, and its five-axis CNC machine tools and milling-turning composite centers occupy a core position in the field of military industry. The company has overcome the blockade on the whole leaf disk of the aviation engine and the missile rudder. And the dynamic precision of the equipment has reached the level of 0.003mm. In recent years, the company has been expanding significantly in the civil market. It provides artificial joint precision machining solutions for medical equipment enterprises, and making technological breakthroughs in the field of new energy automobile motor shell machining, forming a “civil-military integration” dual-wheel drive pattern!

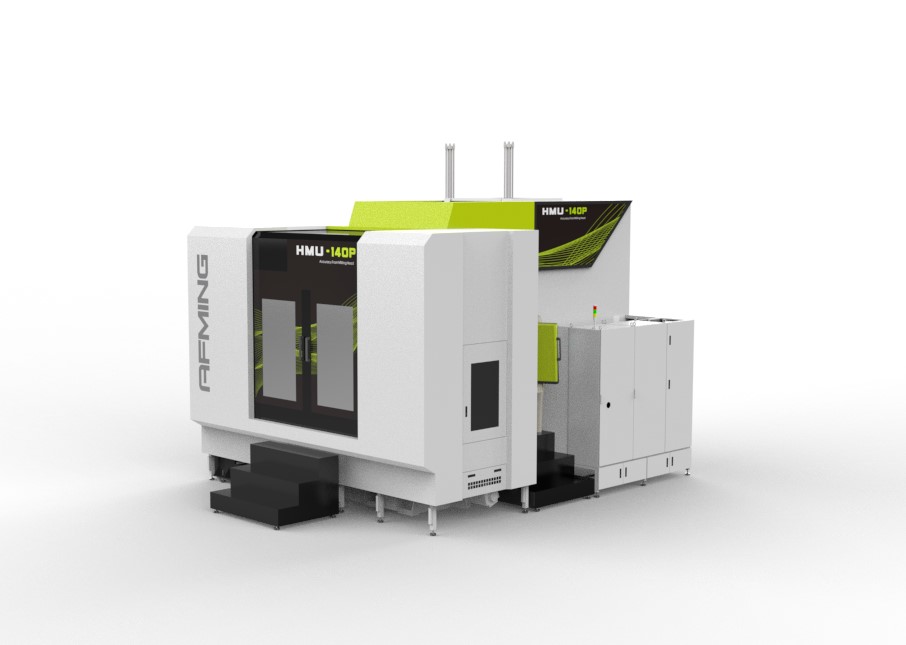

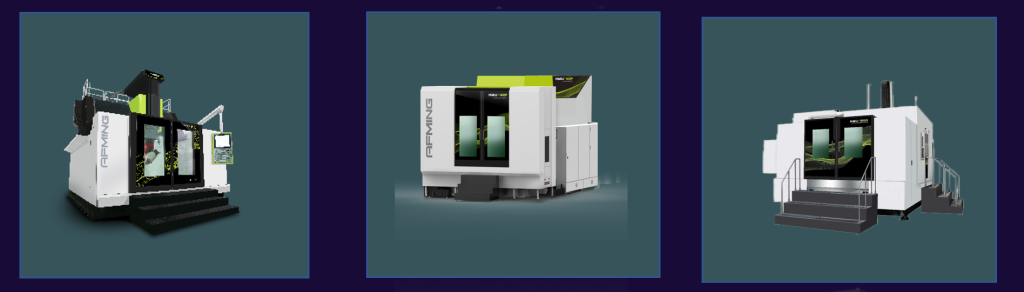

AFMING

AFMING is famous for its cost-effective 5-axis machining centers. Its technology originates from German cooperative research and development. AFMING has realized the technological autonomy and control of the key components such as high-speed spindle, cradle rotary table, pendulum head, etc. And It has established its advantages in the field of complex curved surfaces machining of the impellers and propellers. Its equipment is equipped with a pendulum head rotary table linkage structure, which, together with the intelligent tool tip point following function, can realize one-time clamping and molding of impeller channels with surface roughness up to Ra0.4μm. Through the process package sales model, afming provide customers with a complete set of solutions from programming to tooling. so it significantly reduces the threshold for the use of 5-axis equipment. For Chunli Medical and other enterprises, it provides acetabular cup multi-axis machining solutions. In the field of automotive turbochargers, new energy vehicles, marine propellers, injection molds, it have also gained rapid growth.

Haitian Precision

Haitian Precision offers a wide range of 5-axis machine tools. It can fully meet the machining needs of the aerospace industry for aluminum or titanium alloy structural parts, engine parts, and composite workpieces. In addition, Haitian Precision also realizes independent research and development and production of core components of 5-axis machine tools, such as direct-driven 5-axis milling head, direct-driven cradle rotary table, precision electric spindle and other key components.

CATO CNC

CATO CNC focuses on the market of high-speed drilling and tapping centers for the 3C electronics industry. And its five-axis linkage machine tool occupies a leading position in the field of precision structural parts machining, such as cell phone middle frames and laptop computer pivots. The equipment adopts linear motor drive technology, tapping speed of 6000rpm or more. With self-developed vision positioning system, to achieve ± 0.002mm repeatable positioning accuracy. In recent years, it provides high-speed and high-precision machining solutions for micro components such as connectors and heat dissipation modules. And it has also made breakthroughs in the 5G base station filter processing market.

Himile

Himile initially focused on the research and development of special equipment for tire molds. Then it gradually mastered key technologies such as EDM machine tools, CNC engraving machines and five-axis machine tools. Focusing on heavy-duty CNC machine tools and special production lines, it has established technical barriers in the field of wind power gearbox processing. Its self-developed 10-meter-class CNC gear hobbing machine with thermal deformation compensation technology. So it can stably process wind power gears above 5MW, with tooth surface accuracy up to ISO 3 standard. In recent years, the company has jointly developed an intelligent production line management system with Siemens, realizing the automation of the whole process from blanks to finished products.

Yiteli Technology

Yiteli Technology specializes in high-speed cutting technology for aerospace aluminum alloys. And its 5-axis gantry machining centers have outstanding performance in the field of machining overall structural parts for aircraft. The equipment is driven by highly dynamic linear motors, with a rapid traverse speed of 120m/min. Together with the self-developed chatter suppression system, it can realize stable machining of large-size thin-walled parts (e.g., wing long trusses), with the wall thickness error controlled within ±0.05mm. In the civil market, the company provides special solutions for processing aluminum profiles for high-speed rail carriages. In recent years, the company has developed composite wing rib automated production line in cooperation with Commercial Aircraft Corporation (COMAC), which promotes the independent manufacturing process of key components for domestic large aircraft.