“Currently, 95% of the (AFMING) five-axis machining centers in our workshop are dedicated to producing humanoid robot joints, achieving a 100% pass rate,” introduced Li Jie, the head of Dongguan lewei Precision Manufacturing Co., Ltd. (hereinafter referred to as lewei).

Stepping into lewei’s workshop, rows of highly efficient GMU series five-axis machining centers are mass-producing the “steel framework” for humanoid robots – from dexterous finger joints to load-bearing hip joint connectors, from intricate thoracic structural components to robust foot sole parts…

Originally a precision manufacturer focused on European and American orders and starting with aluminum processing, lewei transitioned into the precision manufacturing sector in 2017. Its business now spans aerospace, new energy vehicles, and humanoid robotics. Facing challenges with frequent clamping and insufficient precision during multi-process machining on three-axis centers, coupled with the surging demand for complex structural parts in emerging industries, lewei decided to upgrade its equipment by introducing high-performance five-axis machining centers.

Machining Efficiency Boosted by 50%: Five-Axis Tech Breaks the “Involution” Dilemma

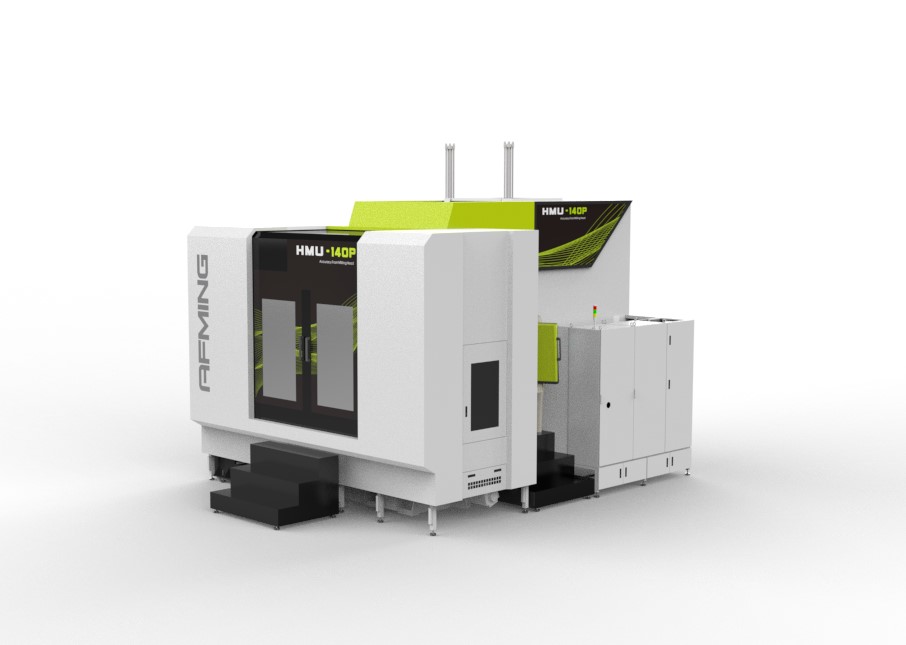

Investing in five-axis wasn’t a trend; it was a necessity for survival. Li Jie candidly stated, “We did it to solve the pain points of efficiency and precision in multi-faceted part machining.” In 2022, after thorough evaluations of several domestic equipment manufacturers, lewei’s team ultimately focused on AFMING’s GMU-800 five-axis machining center, a subsidiary of Topstar. The gantry structure’s key advantage is its exceptional machine rigidity, with precision stability far exceeding expectations. An even bigger surprise was the robust support of “localized service”. AFMING engineers were on-site for commissioning the very day the equipment arrived in the workshop, enabling smooth production start-up the next day – half a month faster than imported equipment!

This GMU-800 five-axis machining center has been in continuous operation for three years, maintaining consistent precision. “During critical delivery periods, a product that previously required 7 machines now only needs 1-2 five-axis machines,” Li Jie detailed the changes. Previously, prototyping humanoid robot parts without five-axis required multiple clamping setups, making precision control difficult. Now, it takes just 2-3 processes, resulting in higher precision, improved efficiency, and significant labor savings. Taking cavity parts for European and American orders as an example: three-axis machining took 24 hours per piece, while five-axis equipment reduced it to just 10.5 hours, boosting efficiency by over 50%.

Precision Reaching 1/3 of a Human Hair: Conquering Humanoid Robot Precision Machining Challenges

“Customer requirements specify dimensional tolerances of 0.02mm-0.03mm and positional tolerance around 0.02mm, equivalent to errors finer than one-third the thickness of a human hair. AFMING’s equipment easily meets this,” Li Jie stated.

The secret behind AFMING’s GMU series achieving “micron-level” efficient production lies in its integration of self-developed high-performance spindles and the high-rigidity, high-torque GTRT gear-driven cradle rotary table technology. This combination ensures both precision stability and production efficiency, providing “hardcore” support for high-precision component manufacturing.

He further added, “Currently, the pass rate for all delivered humanoid robot parts is 100%, resulting in high customer satisfaction.” It is precisely this quality performance that has built lewei’s strong reputation within the industry, attracting more and more humanoid robot industry clients proactively seeking cooperation. High-quality orders are snowballing in growth.

From the second half of 2024 to May 2025, humanoid robot-related orders have already accounted for 50% of lewei’s business. From dexterous hands and arm joints to thoracic structures, hip joints, thigh components, and foot soles, lewei has achieved comprehensive precision machining coverage for the entire range of humanoid robot key structural components.

Facing explosive industry growth, lewei swiftly expanded its production capacity: in 2024, it made another bulk purchase of AFMING equipment, adding 4 GMU-400 and 6 GMU-600 five-axis machining centers, providing robust support for the continuously increasing order demand.

Service as Combat Power: From Precision Machining to Long-Term Partnership

In lewei’s transformation journey, the “reliable” after-sales service provided by AFMING has been repeatedly mentioned by Li Jie as a crucial “reassurance.” From equipment installation to commissioning, engineers provided full support, with exceptionally fast response times to any issues. Li Jie frankly stated, “We are extremely satisfied with AFMING’s after-sales service after more than three years of cooperation.” This “timely, professional, and thorough” service guarantee is precisely why lewei confidently continues to invest its production capacity in AFMING equipment.

Based on this trust, lewei is already planning its next round of capacity upgrades. “We expect to introduce 4-6 more AFMING five-axis machining centers in the future,” Li Jie revealed. Amid the booming humanoid robot industry, AFMING’s five-axis equipment, leveraging its dual advantages of “precision reliability + worry-free service,” is becoming lewei’s strategic production asset for seizing market opportunities.

The humanoid robot industry is experiencing explosive growth, with the market scale poised to surpass the one-million-unit level. AFMING will collaborate with numerous industry clients, providing five-axis machining solutions to jointly embrace the future of the humanoid robot industry.