Core Technology

With a focus on innovation, precision engineering, and advanced materials, our technology and R&D capabilities enable us to deliver high-performance, reliable, and efficient machines that meet the demanding needs of various industries.

Innovation Unleashed: The Powerhouse of 5-Axis Precision

1

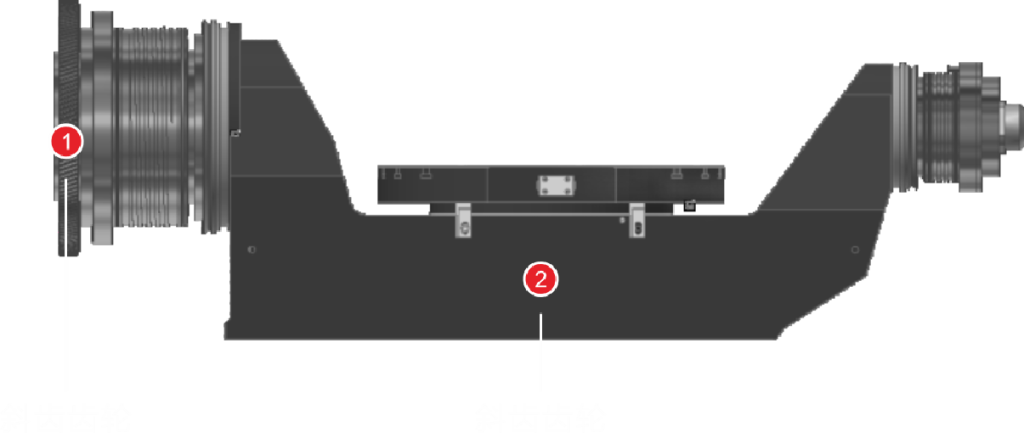

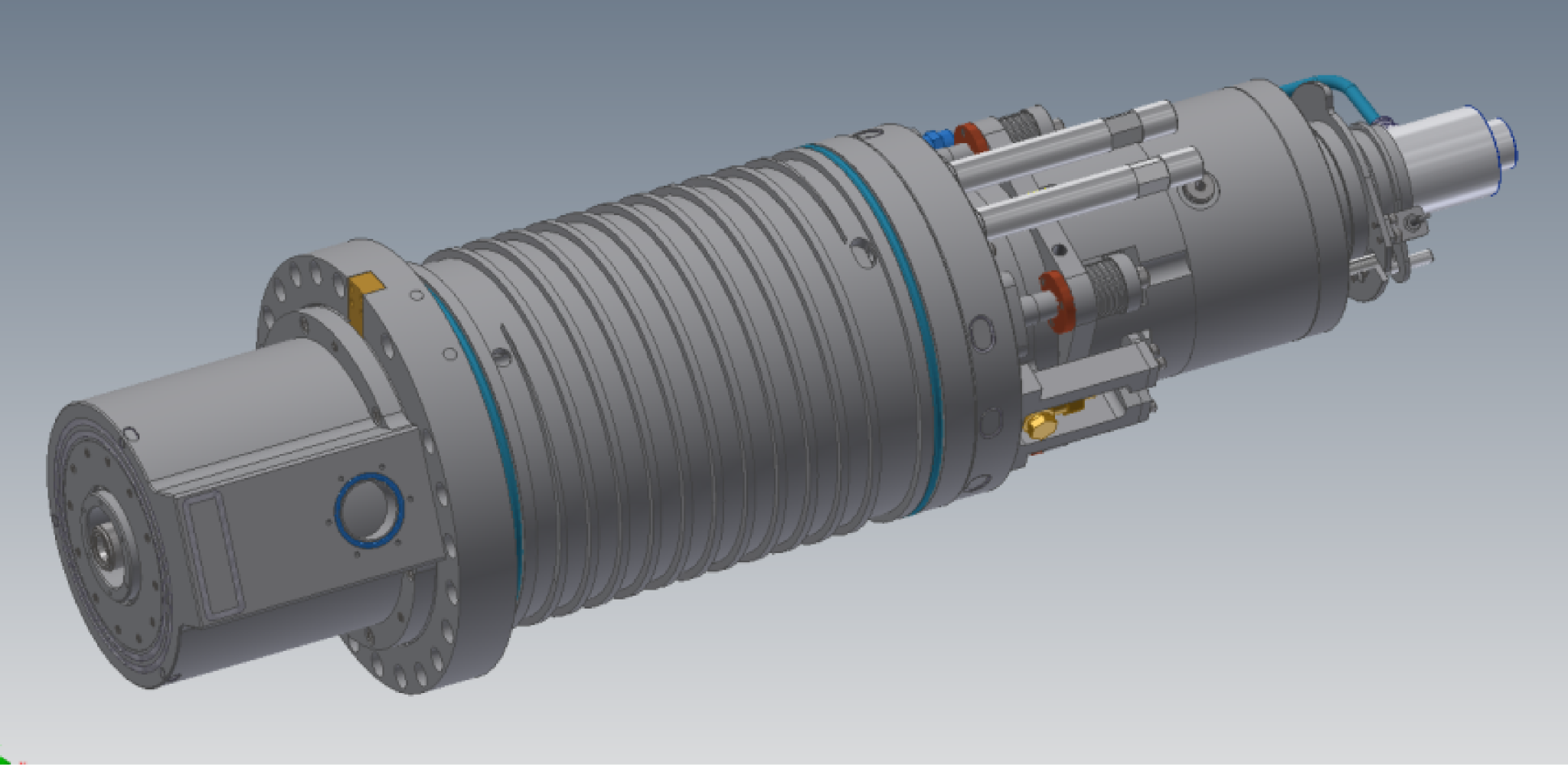

Self-developed spindle

Better surface quality

More stable & higher precision

High-end cooling technology

2

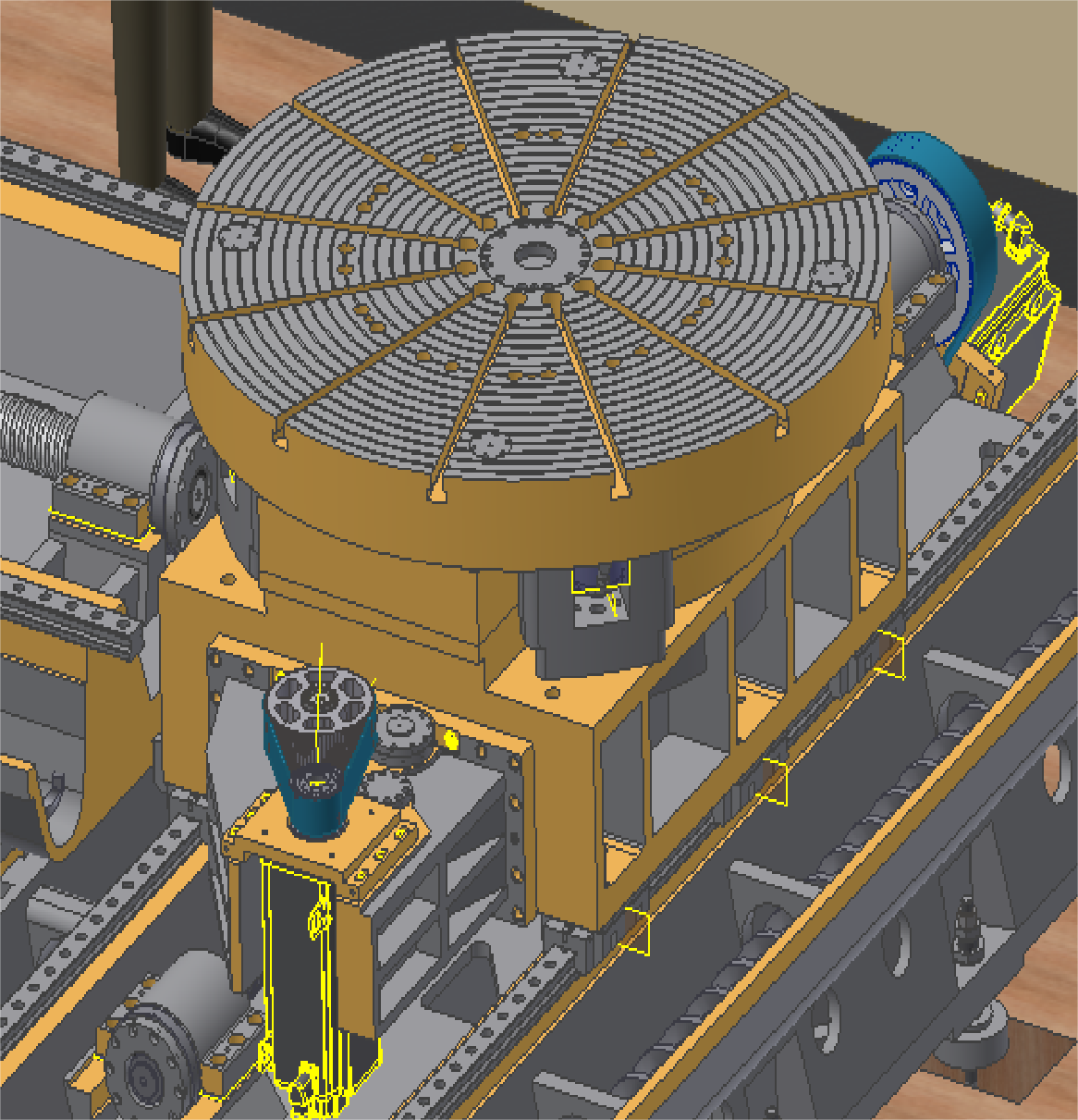

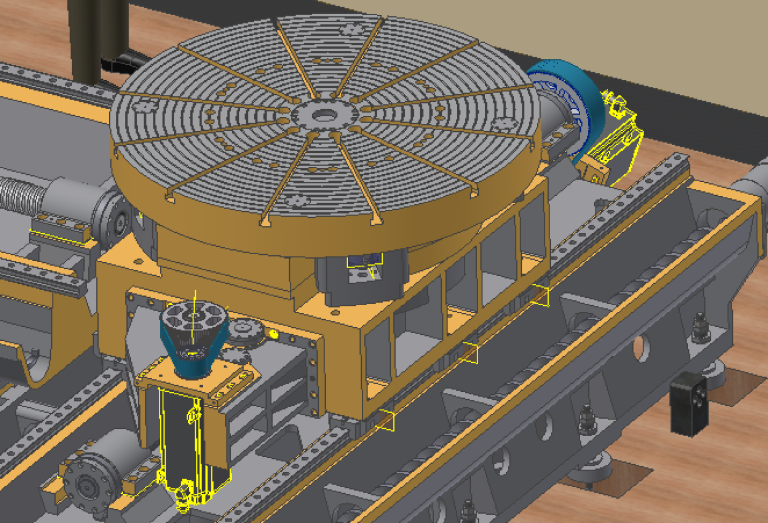

GTRT gear-driven rotary table

Stronger torque output

higher rigidity, stability

better rotation accuracy

3

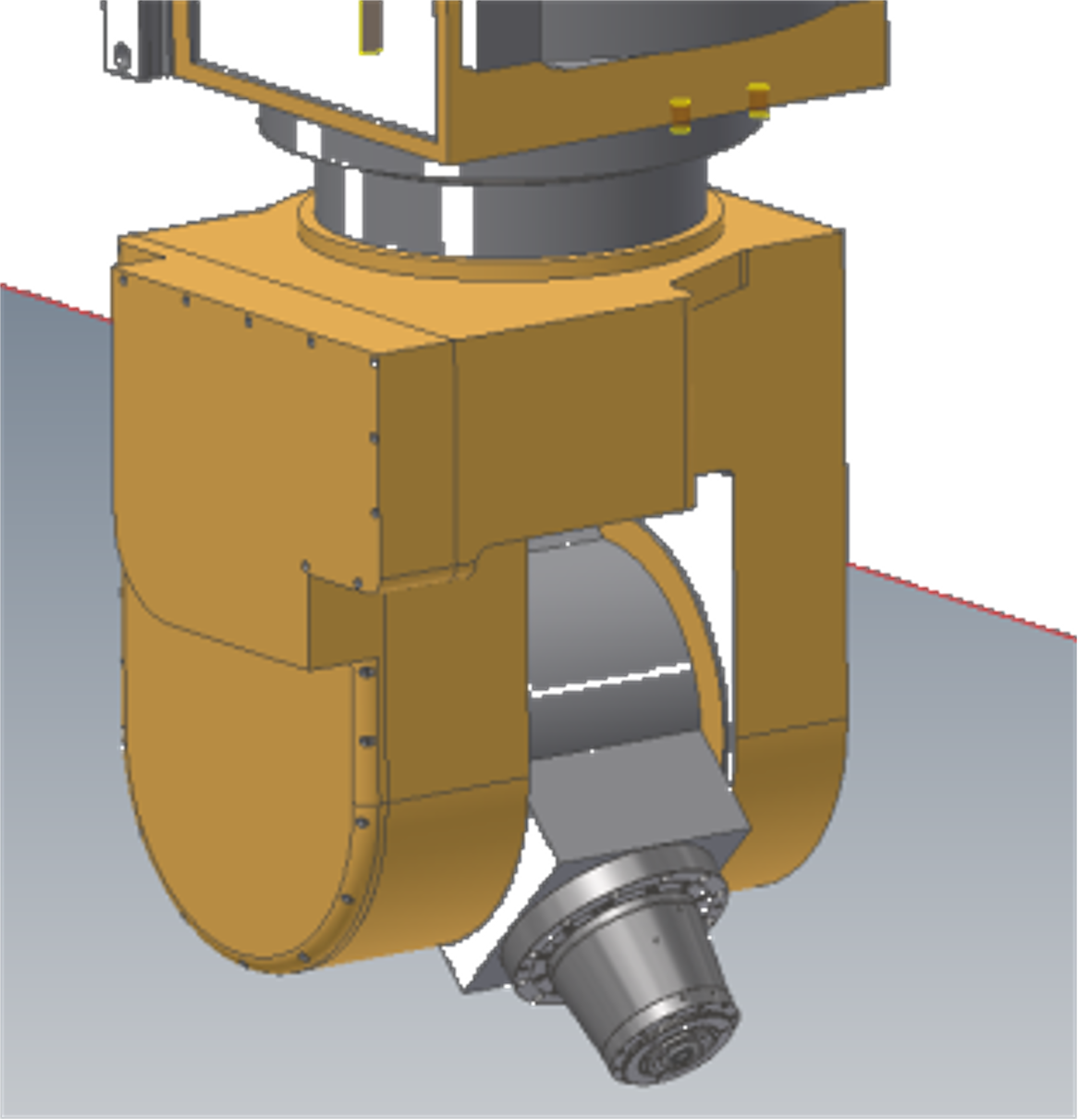

Double swing head

Super rigidity

High precision and stability

Excellent rotation performance

High-end functional parts design & manufacturing capabilities

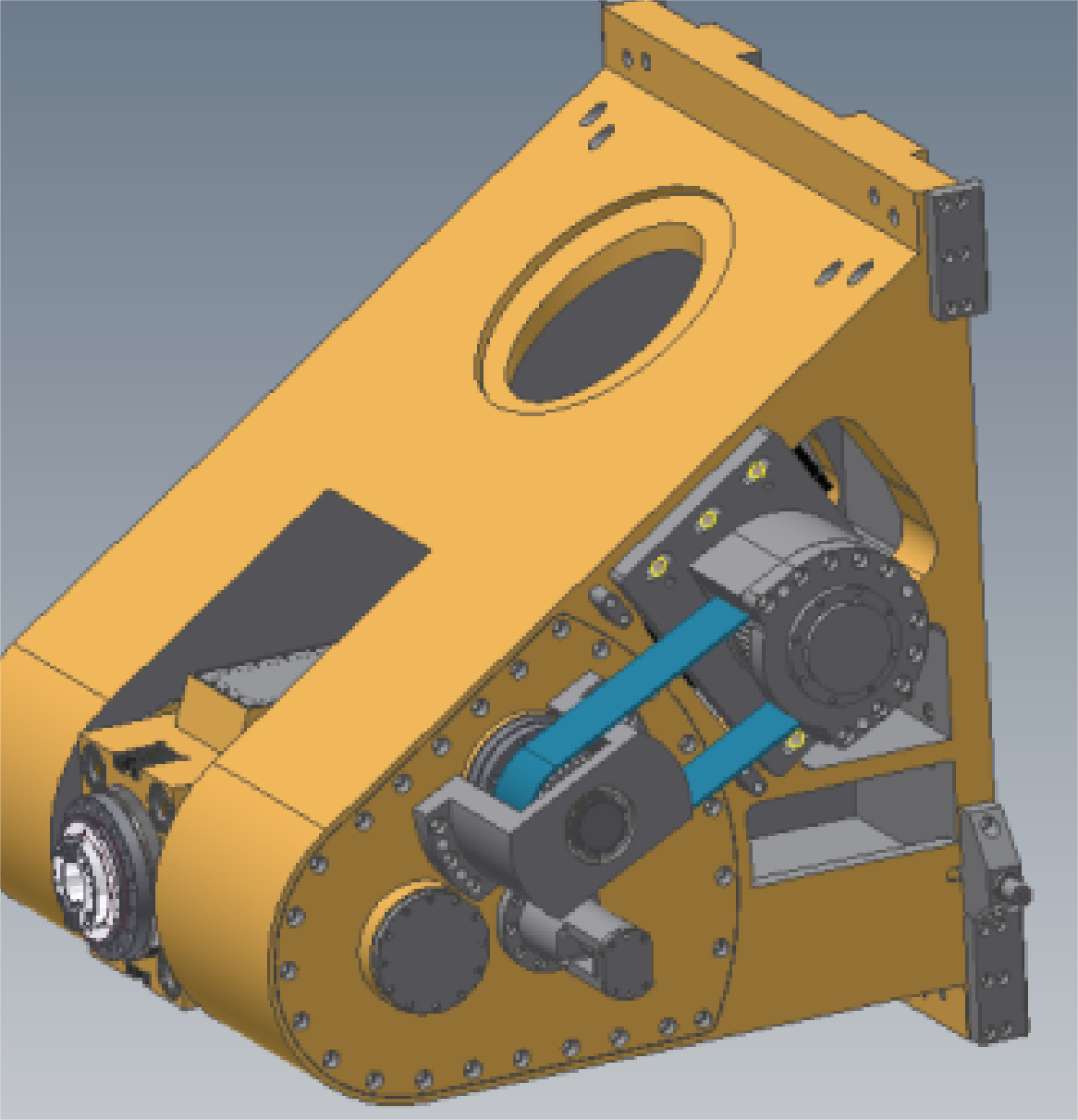

Five-axis linkage swinging fork milling head

Large size precision linkage turntable

High-rigidity single swing milling head

AFMING - Precision In Every Detail

Our high-end machines are powered by cutting-edge core technology that is the result of our robust research and development strength.

From precision components to intelligent control systems, our R&D efforts ensure that our high-end machines stay at the forefront of technological advancement, offering unparalleled quality and productivity.

GTRT Gear-driven Rotary Table Technology

The cradle turntable adopts high-end mechanical transmission GTRT technology, which achieves stronger torque output, higher rigidity, stability and better rotation accuracy than conventional turntable drives; the turntable A-axis and C-axis are driven by helical gears and have a patented double-stage anti-backlash technology。

Gear drive technology design concept from Europe

+ AFMING gear clearance elimination patented technology

+ A/C shaft is supported on the base wall, with strong guide rigidity and high precision

+ Five-axis linkage processing suitable for heavy milling

+ Applicability to a wide range of processing materials, including processing of high hardness and high toughness materials such as steel and titanium alloy.

+ A/C axis is equipped with circular grating as standard

+ Easier chip removal and cleaning

+ Compared with DDR, worm gear, worm and roller cam, it has the advantages of high torque, high precision, low energy consumption and long life

- A-axis: servo motor + helical gear (patented dual-stage backlash elimination technology)

- C-axis: servo motor + helical gear (patented dual-stage backlash elimination technology)

- A-axis torque 4142NM, to ensure heavy cutting, high-rigidity material processing requirements

Equipped with GTRT gear-driven cradle turntable technology; through heavyweight dynamic optimization design, the high response value of the Z axis is effectively improved, and with the European technology spindle, it achieves better dynamic response and contour processing accuracy; excellent dynamic performance and ultra-high precision; high rigidity, stability and high-efficiency vibration suppression integrated base.

Large size precision linkage turntable

High-rigidity Spindle Technology

AFMING spindle adopts original axis cooling and annular spraying technology to effectively control axis thermal elongation, and the speed reaches the highest level in the industry at 20,000RPM, 0.015MM from cold machine to hot machine, and the axis is stable at 0.001MM after long-term operation after warming up.

It adopts mixed internal cooling channel, ring cooling plus center internal cooling, built-in temperature sensor, real-time monitoring of spindle temperature, which can further stabilize the temperature field of the spindle after switching to different working conditions, improve the stability of the tool tip, and obtain high precision and high surface quality of machined parts; the bearings are jet-cooled and lubricated, and the shaft core is independently cooled, which greatly increases the spindle DN value (the product of the average diameter of the spindle bearing and the maximum spindle speed).

M6 high-speed motorized spindle, jet lubrication and core cooling

Gear transmission double swing head technology

Unique swing head: The five-axis linkage swing head is a swing head of a five-axis linkage machine tool with independent intellectual property rights.

The AC axes of the double swing head are both double-toothed rod gear anti-backlash transmission, with super rigidity. In order to weaken the torsional mode of the milling head body and improve the modal stiffness, a special torsional damping mechanism is set up to reduce the torsional vibration of the milling head body;

The double swing head is equipped with a brake cylinder, with excellent cutting performance and high precision and stability. The A-axis rotation angle is ±120°, and the C-axis rotation angle is ±360°. Two large cross roller bearings are used as shaft supports, which can withstand large axial force, radial force, overturning moment and mixed moment at the same time, and have high rotation accuracy.

Adopt a structure of gear transmission commonly used in Europe, which has a very good and perfect match in precision, rigidity and life.

No Compromises - Precision

Five-axis offset milling head