On April 21st, the world’s attention will be on the grand opening of the 19th China International Machine Tool Show (CIMT2025) in Beijing, which will be held concurrently in the two exhibition areas of China International Exhibition Center (Shunyi Pavilion) and Capital International Convention & Exhibition Center until April 26th. AFMING invites you to visit our booth: B111, Hall W2, China International Exhibition Center (Shunyi Pavilion).

In this exhibition, AFMING will bring five new models, HMU140U, K7, GMU900 (with turning), GMU800, DMU400+Automation, and in order to let you feel the excellent performance of AFMING’s new products more intuitively, during the exhibition, we will carry out a demonstration of high rigidity solutions for precision parts on site. You will witness the stable performance of Evermy machine tools under high rigidity, high speed and high precision machining, and feel their powerful cutting ability and excellent machining accuracy. We are looking forward to your visit, explore the cutting edge of CNC technology with us and expand the application fields of CNC technology.

Exhibition Introduction

Founded in 1989, China International Machine Tool Show (CIMT) is held in Beijing, China every odd-numbered year, and is recognized by the international industry as one of the four international machine tool exhibitions, along with EMO in Europe, IMTS in the U.S. and JIMTOF in Japan. After years of development, superimposed on China’s strong market demand and better industrial policy, CIMT has formed a strong attraction in the global manufacturing industry, which is not only a platform for the display of cutting-edge technology and innovative products, but also a platform for industry exchanges and upstream and downstream interaction, and a wind vane for insight into the latest changes in China’s market demand and rapid response. In the face of today’s unprecedented changes, CIMT2025 has attracted a high degree of attention in the global machine tool and equipment manufacturing industry with its huge display scale and high-end internationalization level.

CIMT2025 first look

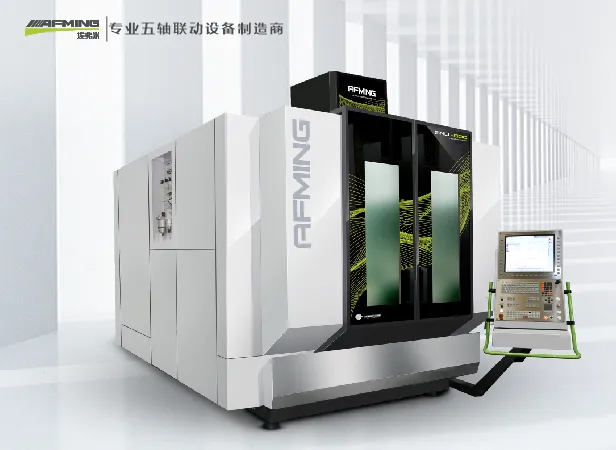

Heavy Duty Cutting 5-Axis Machining Center

GMU800/900 main application scenario for aerospace parts processing, processing materials are usually high temperature alloys, titanium alloys and other hard-to-cut materials, compared with aluminum alloys, high temperature alloys are more ductile, more difficult to cut, which puts forward a very high demand on the performance of the machine tool. GMU800/900 has a strong rigidity of the machine body, can take into account both the rigidity and precision, excellent to deal with the user’s demanding processing requirements. The GMU800/900 has a strong body rigidity, which is able to combine both rigidity and precision, and is an excellent response to users’ demanding machining requirements.

Realization of high-precision 5-axis simultaneous machining center

DMU400 5-axis linkage machining center adopts the cantilever structures, X, Y, Z axes are placed on the upper part of the bed, and the cradle rotary table rotates around the Y-axis as B-axis, and rotates around the Z-axis as C-axis. During the design, the dynamics is optimized by FEA to achieve the best matching of the whole machine structure in terms of mass, stiffness and damping, so as to reduce the cross-motion flexibility between the tool tip and the workpiece, improve the regenerative chatter limit during roughing, and increase the roughing cutting volume, so as to achieve the purpose of high-efficiency cutting. At the same time, due to the reduction of the relative amplitude between the tip of the tool and the workpiece, it improves the surface roughness during machining, reduces the vibration speed of the tip of the tool, and reduces the wear of the tool.

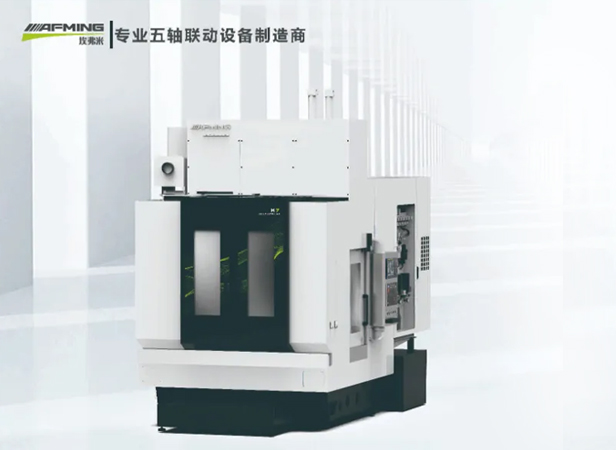

Five-axis linkage machine center for precision parts

K7 is a 5-axis machining center developed for high-speed, high-precision and high-value-added positioning, configured with high dynamic response drive lightweight design, especially suitable for multi-face and 5-axis high-speed and high-efficiency machining of die-cast aluminum automotive complex parts.

K7 is a moving column structure, X / Y / Z axis are high response ball screw drive, X axis left and right feed acceleration of 1g, Y axis up and down feed acceleration of 1g, Z axis ram feed acceleration of 1.5g, the workpiece through a one-time clamping, to achieve multi-face milling machining, greatly reducing the time in the system, is a highly efficient, high-precision die-cast aluminum automotive parts processing tool.

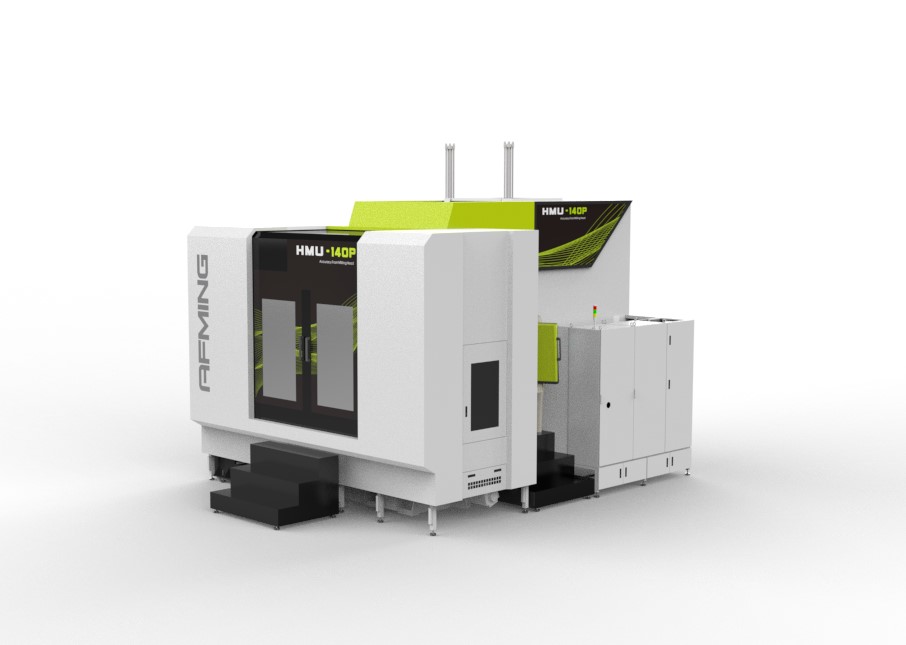

Precision parts high rigidity five-axis linkage machining center

HMU-140U is a horizontal 5-axis linkage machining center developed with high steel, high speed, high precision and high value-added orientation, which is widely used for multi-face and 5-axis linkage machining of complex parts in large-scale moulds and dies, automobile parts, industrial machinery, structural parts of civil aviation and other related industries.

It realizes multi-face milling machining by one-time clamping of the workpiece, significantly shortens the in-process time, and utilizes advanced tooling and high-speed machining technology to significantly reduce the machining time.