The AFMING GMU-800 is one of the few 5-axis machining centers capable of heavy-duty milling. Featuring an overhead gantry structure design, it integrates high-performance spindle technology and a high-rigidity, high-torque gear-driven A/C rotary table. With exceptional rigidity, precision, reliability, and stability, it effortlessly meets machining requirements for diverse materials.

GMU-800 5-Axis Machining Center

Four Core Highlights of GMU800 5-axis machining centers

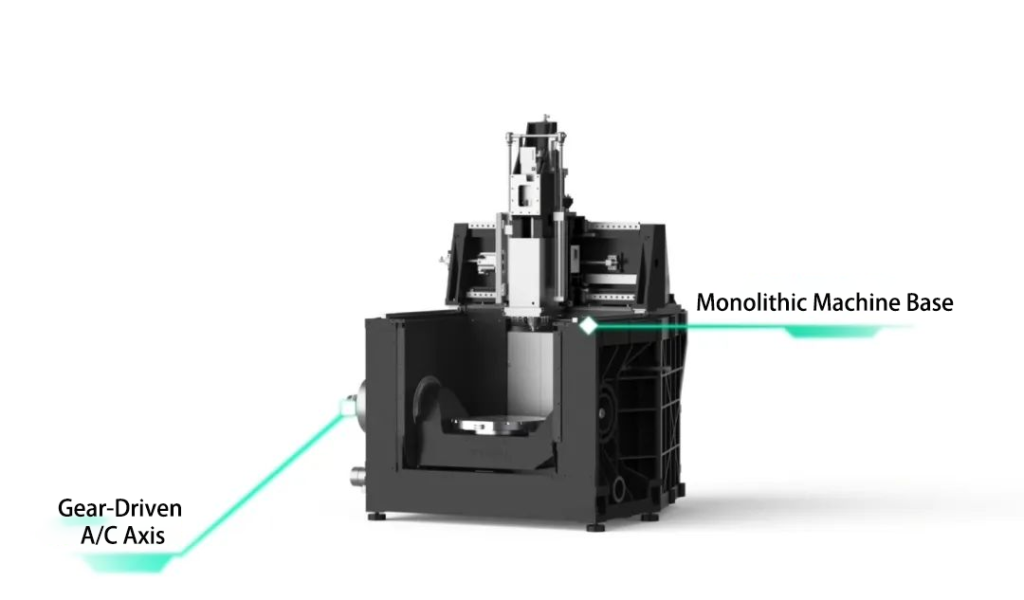

Self-Developed High-Precision Gear Drive System

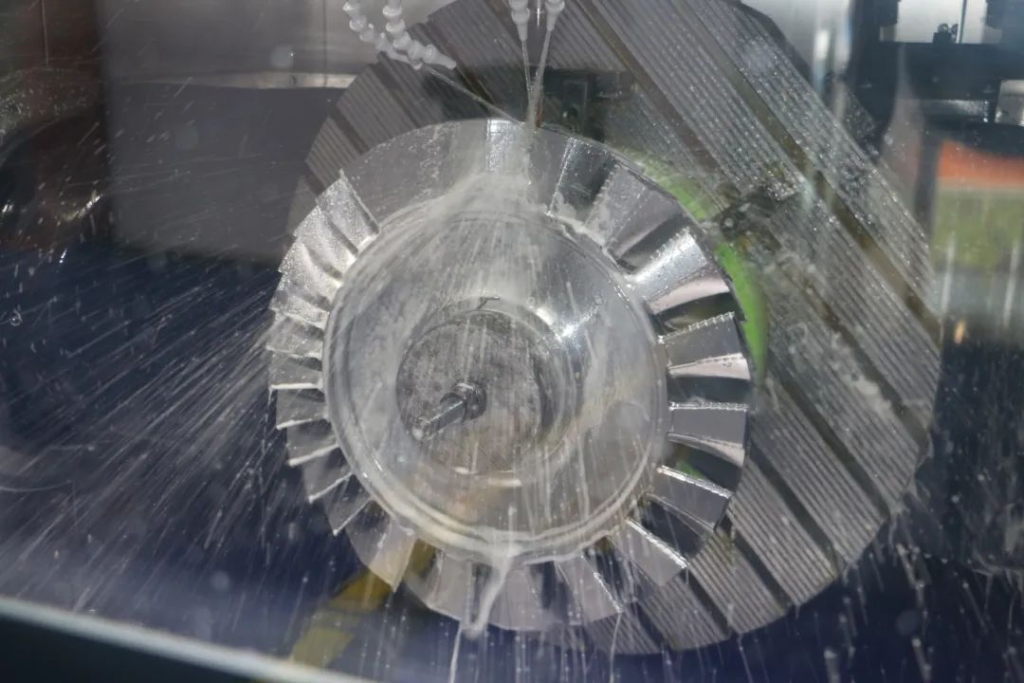

Equipped with dual servo motors + helical gear structure, delivering A-axis torque: 4,142 Nm and C-axis torque: 1,950 Nm, with a load capacity of 800 kg. Patented two-stage backlash elimination technology ensures near-zero transmission clearance, enabling high torque with low energy consumption — ideal for aerospace and complex mold surface machining.

Roughing/Finishing of Impellers in Single Setup: 35% Higher Efficiency vs. Traditional Methods

Z-Axis: High Dynamic Response

Kinematic optimization design combined with patented internal/external spacer cooling spindle technology effectively suppresses thermal deformation and machining vibration, achieving superior dynamic response and contouring accuracy.

Base: High Rigidity

The robust base and column firmly support the A/C rotary table, significantly enhancing guiding precision and rigidity, providing a solid foundation for heavy-duty cutting operations.

Crossbeam: High Performance

The monolithic crossbeam adopts a large-span rigid support structure paired with high-response ball screw drive technology, enabling efficient high-speed machining. Separation of moving components and cutting zones ensures long-term machine stability.

Whole-Machine Computational Analysis Technology

Utilizing Finite Element Analysis (FEA) and dynamic optimization technology to precisely calculate and enhance the dynamic rigidity of all components. Significantly reduces positioning time, minimizes feed lag, and delivers high precision, low failure rates, and extended service life.

Broad Industry Adaptability

GMU800 5-axis machining centers serves diverse sectors including large-scale molds, automotive parts, aerospace components, and industrial machinery. Capable of machining challenging materials (titanium alloys, high-temperature alloys) as well as common aluminum alloys, meeting stringent customer requirements.

AFMING empowers you to break through machining bottlenecks in pursuit of precision, efficiency, and reliability, securing a echnological competitive edge!

Welcome to inquire — AFMING’s engineering team will provide customized machining solutions!