With the high-end manufacturing industry for complex parts, lightweight design and efficient production of the pursuit of continuous upgrading, five-axis machining centers are from the “high-end options” gradually transformed into “core productivity tools. The global 5-axis machine tool market is growing at a compound annual growth rate of over 8%.

Advantages of 5-axis CNC machining center

Five-axis simultaneous processing

Through the coordinated movement of X/Y/Z linear axes and A/B rotary axes, it realizes cutting at any angle in space, and easily completes impellers, shaped surfaces, and other complex structures that are difficult to reach by traditional machine tools. The synchronized multi-axis motion achieves optimal tool orientation, improves surface finish, and reduces vibration, thus extending tool life.

Single-clamping full-process molding

Avoid cumulative errors caused by multiple positioning, and increase machining accuracy by more than 50%, especially suitable for deformable workpieces such as thin-walled parts and micro-fine parts.

Reduced cycle times

By tilting the tool or workpiece, these machines can machine hard-to-reach features such as undercuts and compound angles, reducing production times by up to 50% compared to traditional 3-axis methods.

Dynamic stability

The rigid structure of the 5-axis machine can withstand high-speed cutting loads, and the intelligent temperature control and error compensation technology ensures accuracy fluctuations of ≤ ±0.005mm in continuous machining.

Despite the significant advantages of 5-axis CNC machining center, the application popularization rate is less than 15%. Aerospace complex structural components, medical implants, new energy vehicles integrated die-casting molds, etc., the five-axis linkage machining, micron-level precision, multi-material adaptability requirements continue to rise; small and medium-sized enterprises are limited by the high cost of equipment, maintenance complexity and other issues.

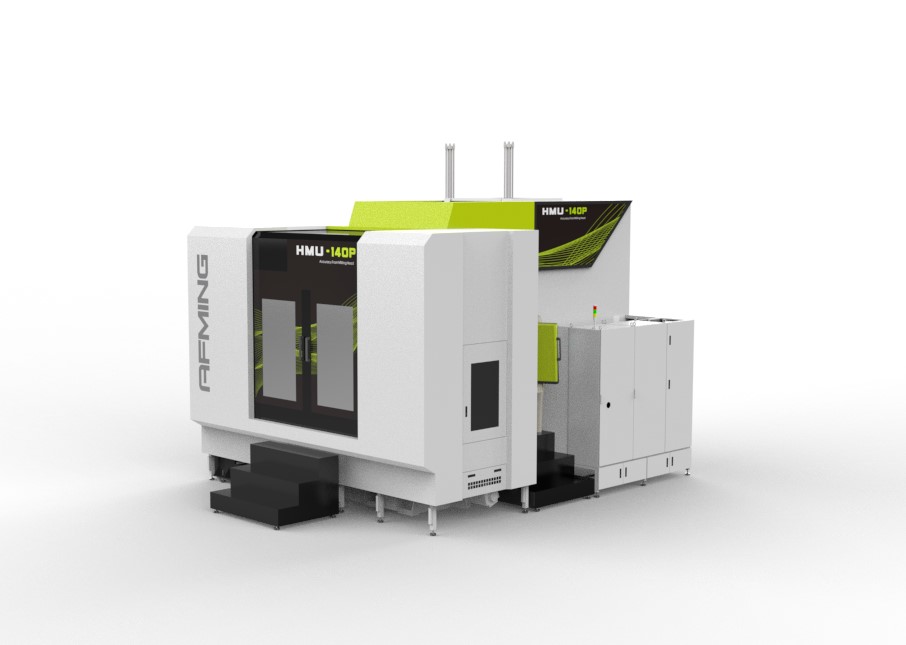

The five-axis machine tools of AFMING has its own core technology and intellectual property rights, structure of the independent design, the key components of their own R & D, and to achieve price advantages. Our large models of five-axis price may be 0.5 times that of the same type of foreign well-known, and machine tool energy consumption is relatively low, the machine tool life is relatively long, low maintenance costs, so that the five-axis machine tool into the large and medium-sized enterprises, so that precision manufacturing is not high on the list.