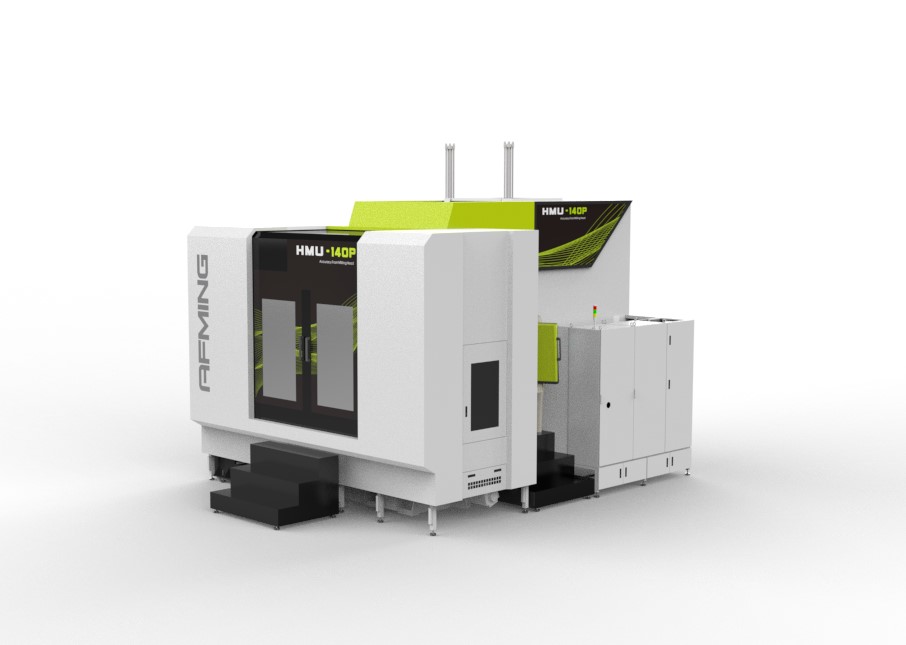

Engineered specifically for heavy, complex components in aerospace, marine propellers, and energy equipment, the HMU140U horizontal 5-axis machining center enables complete machining in a single setup. It overcomes the traditional trade-offs between rigidity, efficiency, and precision.

Three Key Technological Advantages of HMU140U CNC 5-Axis Machining Center:

Exceptional Mechanical Rigidity

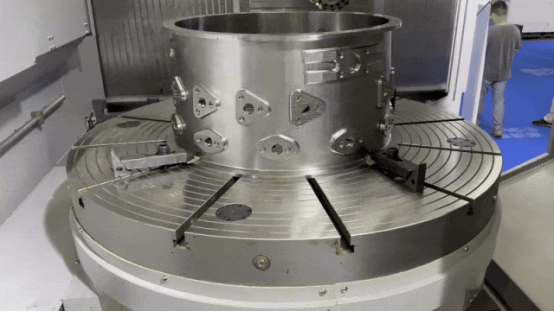

Fixed Table Design: Innovative horizontal structure separates the spindle head and table, allowing independent movement. This drastically increases acceleration and responsiveness while minimizing vibration during machining, delivering unparalleled stability and rigidity.

45° Non-Orthogonal Universal Milling Head: Enables seamless switching between horizontal and vertical machining. Combined with a gear-driven swivel axis, it offers superior mechanical rigidity and an expanded machining envelope.

Topology-Optimized Bed: Finite Element Analysis (FEA) strategically reinforces critical load points, enhancing strength where needed while reducing overall weight.

High-Precision Machining Capability

Robust Mechanical Spindle: Features a taper gear transmission with 2-speed gearbox. Delivers exceptional cutting rigidity for demanding heavy roughing while maintaining the quality required for precision finishing, significantly widening the machining scope.

Precision Linear Motion: All three linear axes (X, Y, Z) utilize high-precision ball screws paired with robust 55mm roller guides. The Y-axis incorporates a high-precision hydraulic counterbalance system, effectively countering gravity-induced wear and ensuring consistent motion accuracy and rapid response.

High-Rigidity Rotary Axes: B/C axes employ high-strength anti-backlash gear drives, guaranteeing smooth, stable torque output even at high rotational speeds.

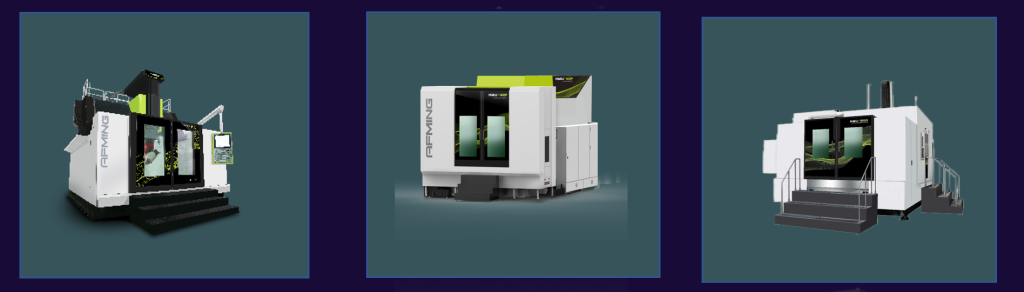

Unmatched Application Versatility of HMU140U CNC 5-Axis Machining Center

The HMU140U is the ideal solution for machining complex workpieces from materials including aluminum alloys, cast iron, and stainless steel. Its efficiency advantages are particularly significant in scenarios demanding heavy cutting and simultaneous 5-axis machining.

Aerospace Structures: Wing spars, engine housings

Marine & Heavy Industry: Propeller impellers, rudder core components

Energy Equipment: Turbine casings, hydraulic valve blocks

Precision Molds: Automotive die-casting molds, medical injection molds

AFMING HMU140U CNC 5-Axis Machining Center: Reconstructing the boundaries of heavy industry machining with aerospace-grade precision standards—excelling in everything from high-temperature alloy cutting to composite material finishing, from prototype runs to volume production. Achieve the “Ultimate Machining Solution” in high-end manufacturing.