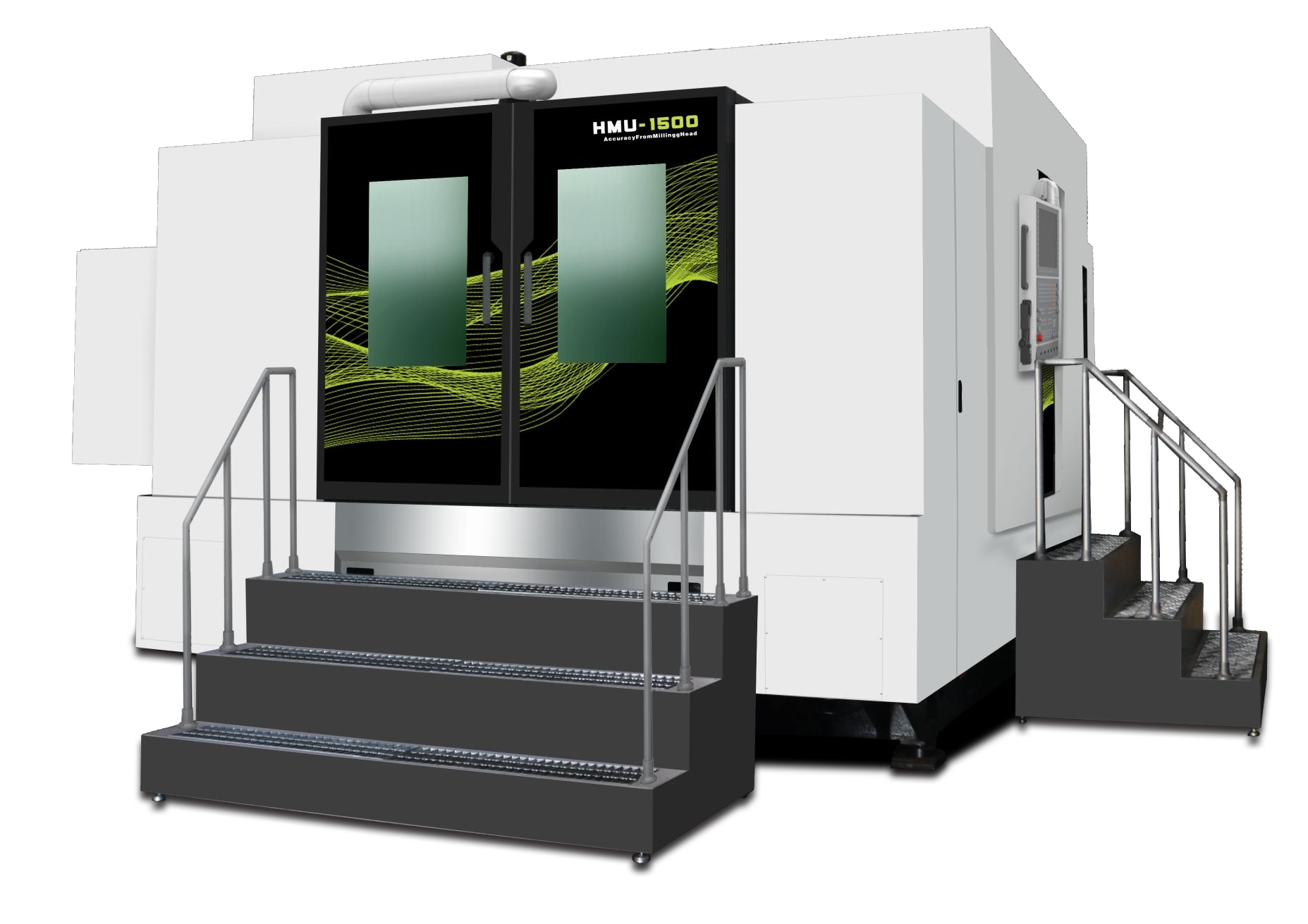

How about our HMU1500 Five-axis Horizontal Machining Center ?

The HMU1500 large cradle 5 axis horizontal machining center adopts a wall structure and is equipped with a high rigidity and high torque gear transmission turntable independently developed by AFMING. The whole machine frame has excellent rigidity, fast response, and stable accuracy.

HMU1500 5-axis Machining Center Advantages:

1, Adopt a wall structure

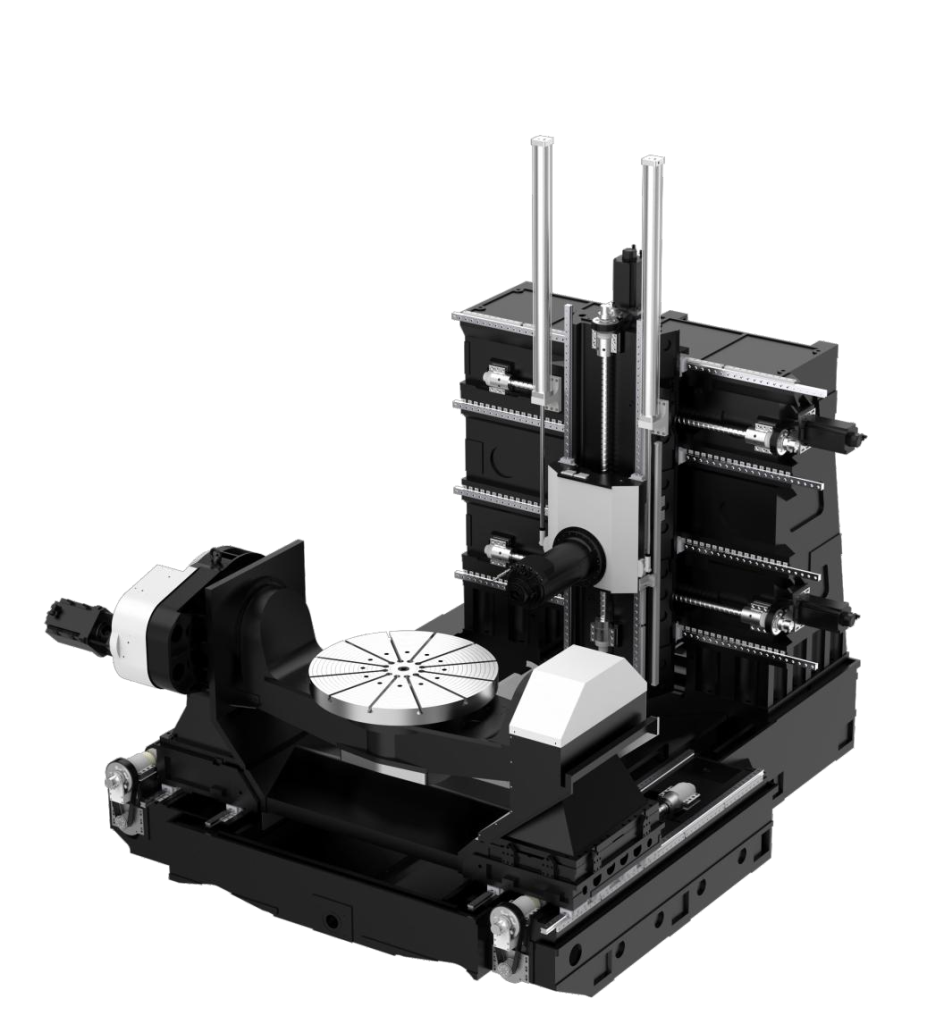

The HMU1500 horizontal five axis linkage machining center adopts a wall structure, with the large drag plate moving forward and backward on the X-axis, and the milling head box carrying the spindle moving up and down on the Y-axis. The Z-axis represents the left and right movement of the cradle workbench, the cradle workbench swings around the X-axis to the A-axis, and the turntable rotates around the Y-axis to the B-axis.

- Spindle head length: 850mm, suitable for deep processing of the inner cavity of the shell.

- The horizontal structure is more convenient for iron filings to be discharged and for loading and unloading.

- The maximum torque of the A-axis is equipped with an innovative gear drive structure, with a rated torque of 6500N.

- Three axis linear displacement speeds of 40 and 60m/min

- The three-axis acceleration reaches 0.6G.

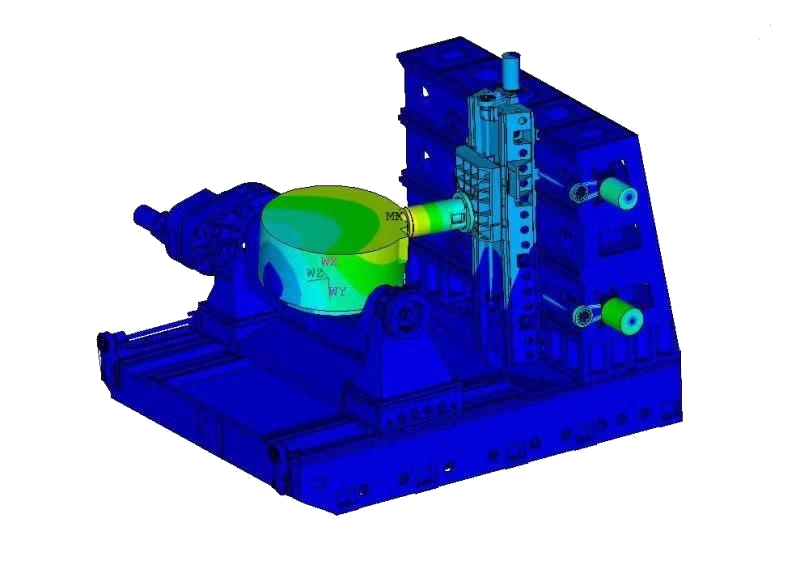

- Finite element analysis and dynamics optimization are used to greatly improve the performance of the entire machine.

- The static and modal analysis of the entire machine greatly improves the static and dynamic characteristics of the machine tool to ensure its overall rigidity, stability, and dynamic performance.

- By increasing the natural frequency and cutoff frequency of the feed drive system, the positioning time and hysteresis of the feed system can be effectively reduced, achieving high response dynamic performance and high-speed machining contour accuracy.

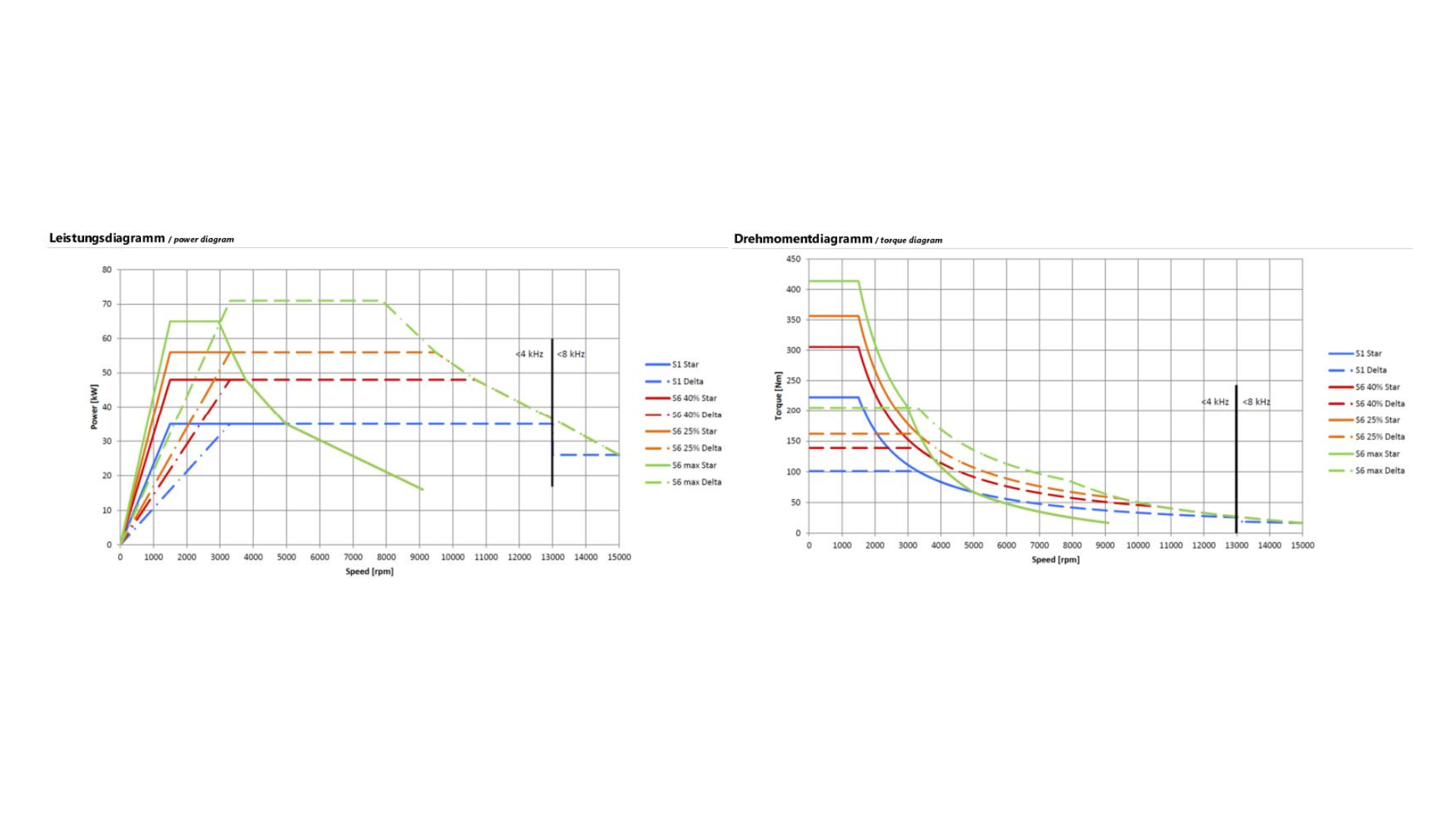

2, High rigidity electric spindle

the five axis horizontal machine center equips a 15000rpm spindle option, suitable for large structural components in civil aviation and aerospace, covering all processing conditions of aluminum alloy subframe parts, maximizing processing efficiency.

| 15000rpm Electric Spindle HSK-A100 | |

| Spindle power (S1): | 48 KW |

| Spindle torque (S6) : | 305 Nm. |

3, GTRT gear driven rotary table swing angle milling head technology

The HMU-1500 5-axis horizontal machining center turntable adopts patented mechanical transmission GTRT technology, which achieves more powerful torque output, higher rigidity, stability, and better rotation accuracy than conventional turntable drives.

- + Dynamic optimization through FEA, effectively improve the anti-vibration of the whole machine.

- +Accurately calculate the optimal dynamic rigidity under actual working conditions.

- +Improve the natural frequency and cutoff frequency of the feed drive system, effectively reduce the positioning time and the lag of the feed system to achieve high response dynamic performance and high- speed machining profile accuracy.

| Worktable Size | 1250mm |

| A-axis rated torque | 6500N.m |

| B- axis rated torque | 1340N.m |

| Load bearing capacity | 1000kg |

4, Finite Element Analysis and Dynamic Optimization

During the design process, FEA is used for dynamic optimization to achieve the optimal matching of the overall structural quality, stiffness, and damping, thereby reducing the cross dynamic flexibility between the tool tip and the workpiece, improving the regenerative vibration limit during rough machining, increasing the cutting amount of rough machining, and achieving the goal of efficient cutting. At the same time, due to the decrease in relative amplitude between the tool tip and the workpiece, the surface smoothness during processing is improved, the vibration speed of the tool tip is reduced, and tool wear is reduced.

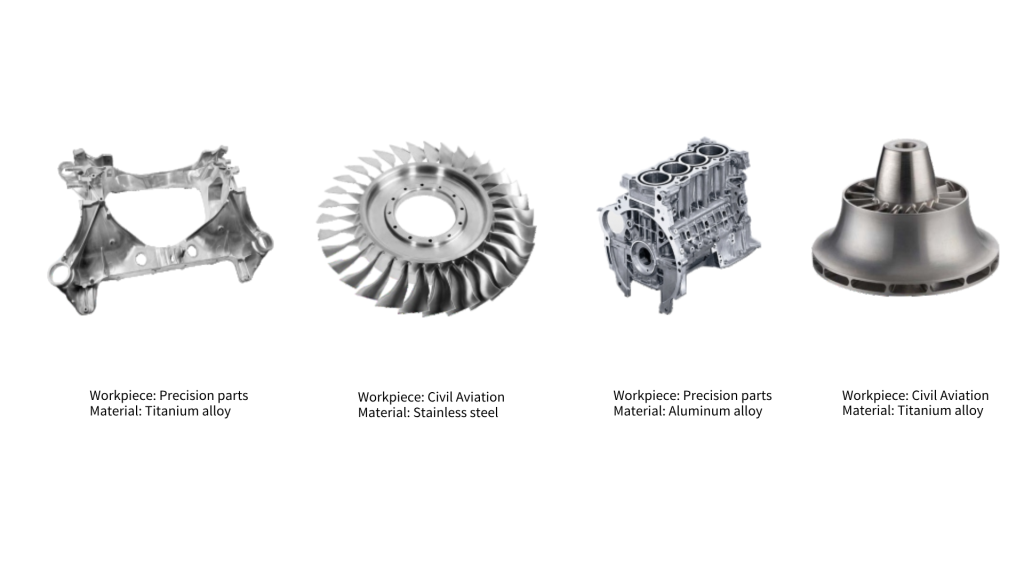

HMU1500 5-axis Horizontal Machining Center Application:

Application area: +Civil aviation +Shipbuilding Industry +Construction machinery +Mold industry

Main Specifications of HMU1500 Five-axis Simultaneous Machining Center

| Item | Unit | HMU-1500 | |

| Systems (Control Units) |

System | Heidenhaini TNC640 | |

| Worktable | X/Y/Z axis travel | mm | 1600/1600/1200 |

| A/B axis travel | degree | +-120/360(unlimited) | |

| Worktable size/maximum load capacity | Mm/kg | Φ1250/1000kg(round worktable) | |

| Maximum clamping diameter of worktable | mm | Φ1500 | |

| Distance from worktable surface to spindle nose | mm | 170-1370 | |

| Distance from worktable center to spindle nose | mm | 120-1320 | |

| A-axis rated torque/brake torque | N.m | 6500/12000 | |

| B-axis rated torque/brake torque | N.m | 1340/6000 | |

| Spindle | Max.spindle speed/tapered shank | Rpm/hol ders |

15000/HSK-A100 |

| Spindle power | kw | 48 | |

| Spindle torque | N.m | 305 | |

| Feeding System | X/Y/Z axis rapid displacement | m/min | 40/40/40 |

| Max.cutting feed rate | m/min | 20 | |

| A/B axis fast feed rate | rpm | 20/50 | |

| Linkage control | 5 axis | ||

| Minimum indexing angle(A,B) | degree | 0.001° | |

| Positioning accuracy ISO10791-4:1998 | X/Y/Z | mm | 0.01/0.01/0.01 |

| A/B | ARCSEC | 12/12 | |

| Repetitive Positioning Accuracy ISO10791-4:1998 | X/Y/Z | mm | 0.008/0.008/0.008 |

| A/B | ARCSEC | 10/10 | |

| Automatic Tool Change System | Number of tools | pcs | 40T |

| Tool change time (tool-to-tool) | sec | 3.5 | |

| Max.tool length | mm | 500 | |

| Max.tool diameter/adjacent no tool | mm | Φ125/Φ200 | |

| Max.tool weight | kg | 20 | |

| Machine dimension | Total height of machine tool | mm | 5000 |

| Floor space (L×W) | mm² | 7800*6100 (with chip conveyor) | |

| Net weight of machine tool | kg | 35000 | |

| Power requirement | kw | 125 | |

HMU1500 5 axis Horizontal Machining Center Standard/Optional

| No. | Standard Configuration | Items | Configuration | |

| 1 | System | Heidenhaini TNC640 | HSK-A100 10000rpm Kessler electric spindle | Power: 50/70kw Torque: 400/560Nm |

| 2 | Sheet metal | Fully enclosed body sheet metal | HSKA100-60T Okada tool magazine | HMU1500-200001 |

| 3 | Spindle | HSK-A100 15000 rpm Kessler Electric spindle | 10 Oil 2 Gas Work bench Fixture Port Assembly | HMU1500M-043730 |

| 4 | A/B pendulum head rotary table | A-axis precision geart ransmission swing head, B-axis Φ1400 precision gear transmission turntable | CTS30 bar spindle center water outlet | |

| 5 | Tool setting instrument | Marposs Contact | CTS50 bar spindle center water outlet | |

| 6 | Spindle cooler | Water cooler (Chinese famous brand) | CTS70 bar spindle center water outlet | |

| 7 | Three axis linear encoder | Heidenhain | System Function Options | Five axis collision prevention |

| 8 | A/B axis rotary encoder | Heidenhain | Post processing services | UGNX Post processing(Heidenhain System) |

| 9 | Tool magazine | HSK-A100/40T flush-mounted tool magazine | Post processing services | Hmp Post processing(Heidenhain System) |

| 10 | Chip removal system | Composite roller chip removal device | Post processing services | Power mill Post processing (HeidenhainSystem) |

| 11 | Guide rail | X-axis 45 roller guide,Y-axis 45 roller guide, Z-axis 45 roller guide (Japan THK/Rexroth) | Post processing services | Master cam Post processing(HeidenhainSystem) |

| 12 | Screws | X-axis R50x20, Y-axis R50x20, Z-axis R63x25 (Japan THK) | Post processing services | On machine measurement and compensation module |

| 13 | Table hydraulic tooling port | Domestic production | Post processing services | The Heidenhain system of NX software foronline alignment and measurement |

| 14 | Z-axis balancing system | Air pressure balancing system(Afming) | ||

| 15 | Electrical box thermostat system | Air conditioner constant temperature | ||

| 16 | Pneumatic system | Japan SMC | ||

| 17 | Grease lubrication system | (A,B-axis drive components, three-axis drive components) | ||

| 18 | Machining area cleaning | Air gun, water gun for cleaning | ||

| 19 | Working lights | LED lighting | ||

| 20 | Warning lights | Three-color warning light | ||

| 21 | Tool box and ground screw | Toolbox and ground screws | ||

| 22 | Five-axis center alignment kit | (with 3D probe) Heidenhain | ||