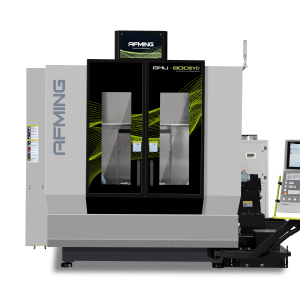

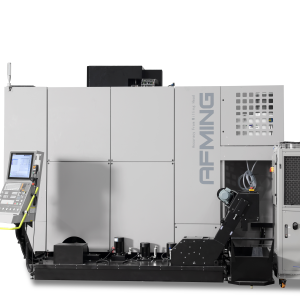

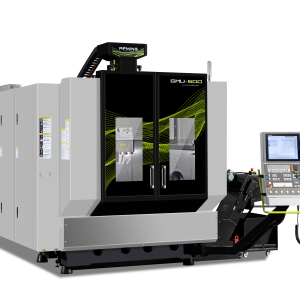

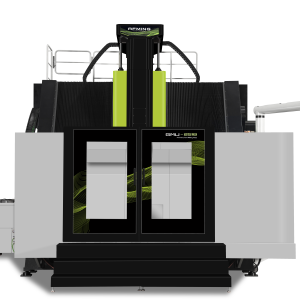

How about our Simultaneous 5-axis CNC Machine Center GMU-800/GMU900?

The GMU800/900 series is currently one of the few 5-axis CNC machine center capable of heavy milling. By adopting high-end German spindle technology, combined with precise analysis and optimization, bed structure and high rigidity and high torque gear transmission A/C cradle turntable technology, the A-axis torque is 4142 Nm, it ensure the machining requirements for heavy cutting and high rigidity materials.

Why Choose our 5-axis CNC Machine Center GMU-800/GMU900?

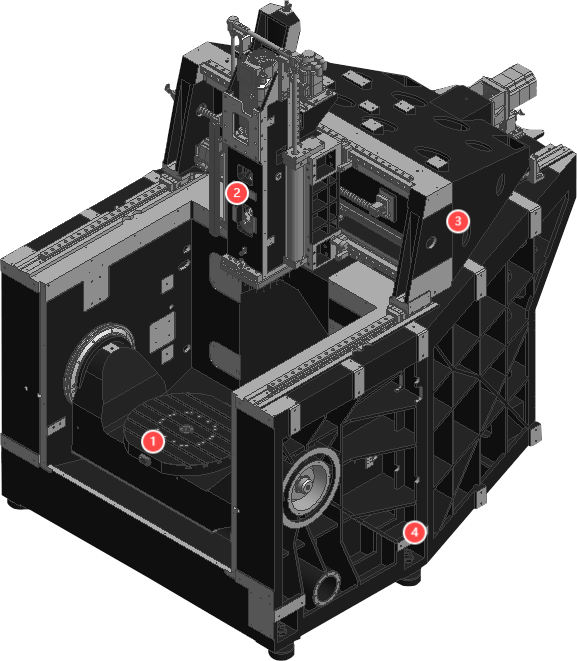

Machine Frame

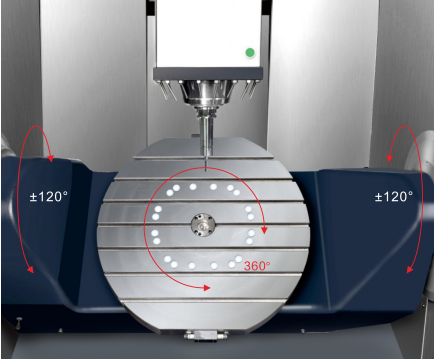

1, A/C axis cradle worktable: Cradle turntable technology with GTRT gear drive

-

+ The A/C axis standard configuration of circular grating

- + Gear backlash patented technology

- + A-axis torque 4142Nm, C-axis torque 1950Nm

- + High torque, low energy consumption

- + Maximum load-bearing capacity is 1000kg

2, Z axis: Through heavyweight dynamic optimization design, the high response value of the Z axis is effectively improved, coupled with European technology spindles, to achieve better dynamic response and contour machining accuracy

- + The spindle adopts patented technology and inner and outer sleeve cooling technology, effectively suppressing thermal deformation and vibration generated during processing.

- + Optional European technology direct coupled mechanical spindle and water-cooled motor with a maximum torque of 119 Nm.

- + Configure a cylinder balance system to reduce the load of the slider on the screw, improve the Z-axis response speed and the service life of the screw.

- + The closest distance between the spindle and the door opening is 390mm, providing the best accessibility.

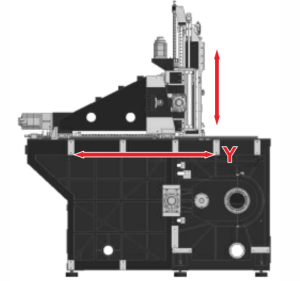

3, Beam: Excellent dynamic performance and ultra-high precision

- + Integrated crossbeam with large span and strong support

- + Four 45mm high rigid roller guides on the Y-axis

- + High response screw drive technology, X/Y/Z acceleration of 7m/s

- + X/Y/Z three-axis standard resolution 0.01 grating ruler

- + The screw with hollow oil cooling technology to effectively suppress thermal expansion

- + Three-axis X/Y/Z moving parts separated from machining and cutting areas to ensure accuracy and durability

4, Base: High rigidity, stability, and efficient shock-absorbing integrated base

- + High specification Mihana cast iron, secondary tempering treatment, and aging treatment for more than six months to ensure the stability of the casting material

- + Accurate finite element analysis and dynamic optimization techniques

- + The integrated base weighs up to 10 tons, ensuring the stability of the entire machine

- + Using multi-point lubrication with grease effectively reduces the failure rate of linear moving parts, ensuring the accuracy and lifespan of the machine tool

- + The base arm strongly supports the A/C cradle pivot, achieving stronger guidance accuracy and rigidity

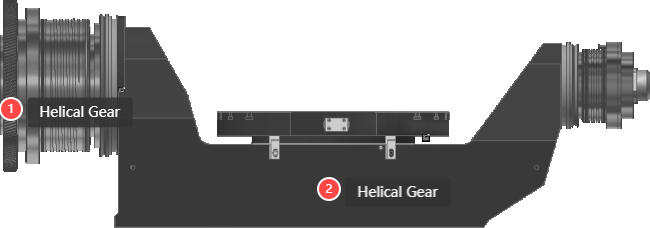

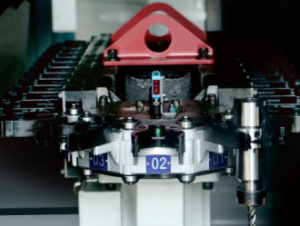

Simultaneous 5-axis CNC Machine Center Equipped with GTRT Gear Driven Turntable Technology

The GMU-800 cradle turntable adopts European high-end mechanical transmission GTRT technology, which achieves greater torque output, higher rigidity, stability, and better rotation accuracy than conventional turntable drives.

- Gear drive technology based on European design philosophy

- AFMing Gear Clearance Patent Technology

- The A/C shaft is supported on the vertical wall of the base, with strong guiding rigidity and high precision

- Five axis linkage machining suitable for heavy-duty milling

- The applicability of widely processed materials, including the processing of high hardness and high toughness materials such as steel and titanium alloys

- The A/C axis comes standard with a circular grating

- Easy chip removal and cleaning

- Compared to DDR, worm gear, worm gear, and roller cam, it has the advantages of high torque, high precision, low energy consumption, and long service life

GTRT gear driven turntable

- A-axis: servo motor+helical gear (patented dual stage clearance technology)

- C-axis: servo motor+helical gear (patented dual stage clearance technology)

- Travel (A/C): ± 120 °/ 360 °

- Maximum speed (A/C): 20/ 30 rpm

- Maximum torque (A/C): 4142/ 1950 N.m

- Accuracy (A/C): 8″/ 5″

- Load bearing capacity: 1000KG

| GMU-800 | GMU-900 | |

| X/Y/Z axis travel | 850/950/550 mm | 900/1050/600 mm |

| Table size | Φ800 | Φ800 |

| A/C axis travel | ±120°/360° | ±120°/360° |

| A/C torque | 4142/1950 N.m | 4142/1950 N.m |

| A/C axis rapid feed rate | 20/30 rpm/min | 20/30 rpm/min |

| A/C positioning accuracy | 6 ARCSEC | 6 ARCSEC |

| A/C repetitive positioning accuracy | 4 ARCSEC | 4 ARCSEC |

| Maximum load | 1000kg | 1000kg |

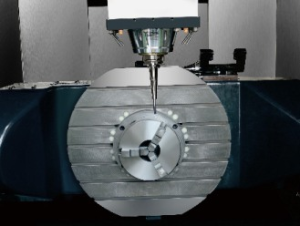

GMU800/900 5-axis CNC Machine Center Super Power Direct Spindle/ Electric Spindle

AFMING direct spindle 15000rpm, AFMING electric spindle 18000rpm, Omlat electric spindle 15000rpm three spindle options. Fully considering general processing, mold processing, civil aviation and aerospace special processing conditions, we provide customized spindle solutions for customers, expand processing range, and improve processing efficiency.

- The sealing at the front end of the spindle comprises a splash ring, a combination labyrinth, and airtightness to prevent cutting fluid and other debris from entering, ensuring spindle accuracy and lifespan

- Hydraulic pressure drives the knife cylinder;

- Mixed internal cooling cooling method;

- The design configures the loosening and reverse locking mechanism so that the cutting force directly applies to the spindle shaft, and the spindle bearing remains unaffected by force, effectively extending the service life of the spindle bearing;

- The spindle material is DIN low-carbon alloy steel, which has undergone carburizing and quenching treatment, and precision cutting;

- The bearing span is iterated to the optimal stiffness, ensuring that the spindle has the best heavy cutting performance advantage

- Adopting a unique hybrid internal cooling channel and external ring cooling, with a built-in temperature sensor to monitor the spindle temperature in real time, so it can further stabilize the temperature field of the spindle after switching between different working conditions, improve the stability of the tool tip, and achieve high precision and surface quality in machining parts;

- Spray cooling lubricates the bearings, greatly increasing the DN value of the main shaft (the product of the average diameter of the main shaft bearings and the maximum speed of the main shaft);

- Spindle thermal elongation ≤ 0.01mm, stable time ≤ 10min, technologically advanced, unique and outstanding

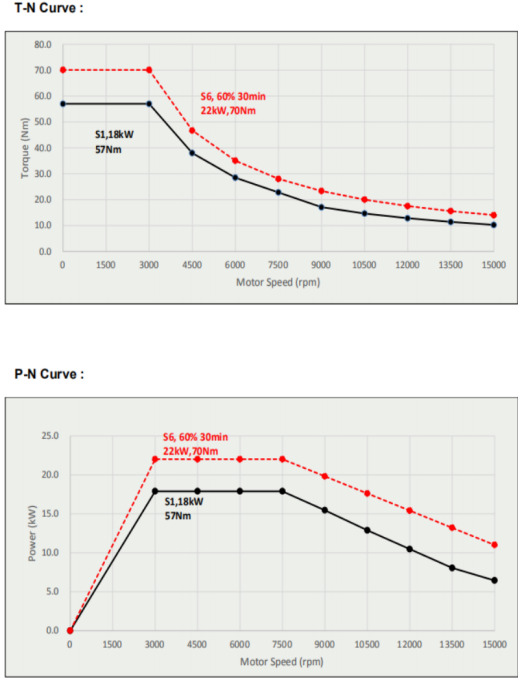

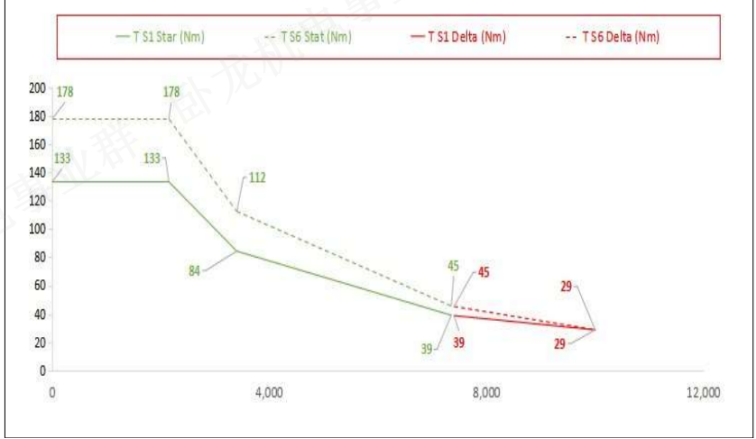

+ HSK-A63 15000rpm AFMING direct spindle

22 kW (S1/S6-40%)

70 N.m (S1/S6-40%)

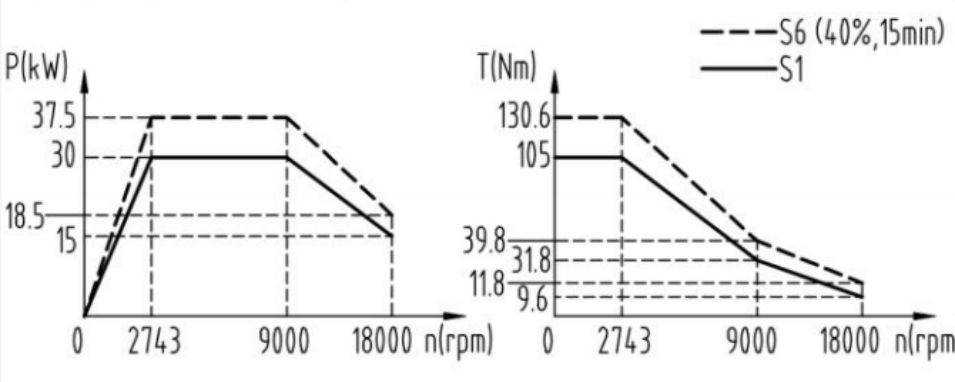

+ HSK-A63 18000rpm AFMING electric spindle

37.5 kW (S1/S6-40%)

130.6 N.m (S1/S6-40%)

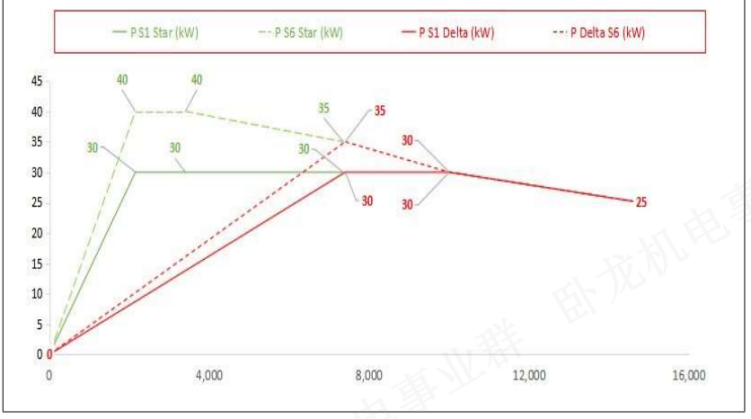

+ HSK-A63 15000rpm OMLAT electric spindle 40 kW (S1/S6-40%) 178 N.m (S1/S6-40%)

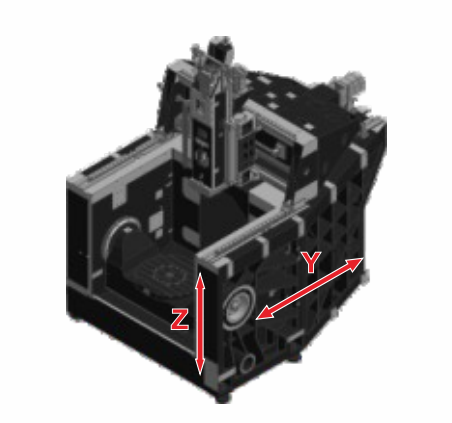

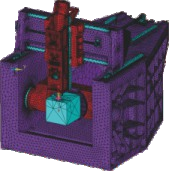

The use of finite element analysis and dynamic optimization greatly improves the performance of the entire machine

The design adopts finite element analysis and dynamic optimization to greatly enhance the static and dynamic characteristics of each component of the machine tool, ensuring the overall rigidity/stability and dynamic performance of the machine tool.

+ Whole machine FEM

+ Accurately calculate the optimal dynamic rigidity under actual working conditions

+ Improve the natural frequency and stop frequency of the feed drive system, effectively reduce positioning time and feed system lag, and achieve high response dynamic performance and high-speed machining contour accuracy

The Y-direction of the crossbeam is greatly driven by a single servo,which improves the synchronization of the dual servo drive structure

The crossbeam adopts a four track multi-point support design, and the front support point Y direction effectively ensures the stability of the slider at the center of gravity in the slider.

Finite Element Analysis (FEA)

The integral bed structure of the overhead crane achieves outstanding rigidity, stability, and precision. Unparalleled dynamic response.

+ X/Y/Z linear axis moves based on the base bed

- No influence of workbench and workpiece load/high dynamic and high precision

- No cutting operation environment impact/low failure, long lifespan

+ The A/C turntable is supported on the vertical wall of the base bed frame

- High rigidity/high load-bearing capacity/high precision/heavy cutting

+ Four roller guides on the Y-axis provide full support throughout the entire process

- Large span/high rigidity/stability/convenient lifting operation

Precision control of 5-axis CNC Machine Center

The positioning accuracy and repeated positioning accuracy of the GMU-800/900 five-axis machining center are in micrometers. Mechanical and machining accuracy is ensured through machine design, component optimization, cooling system and excellent assembly.

| NAS parts accuracy detection | |||

| Circular accuracy | 0.012 mm | (X/Y at feed 3.000 mm/min and radius 100 mm) | |

| NAS | roundness | <0.006 mm | (Tapered fve-axis linkage) |

| flatness | <0.01 mm | (Φ80/300×400 mm) | |

| Surface roughness | Ra1.6-0.8 | (Φ80/300×400 mm) | |

| Dependng on the measured environment and processing condtions and other factors,there may be differences fom the data recorded in the product catalog | |||

+ High precision roller line rail

- High rigidity 45mm roller line rail, accuracy up to P level, providing accurate and stable linear feed motion characteristics

+ Roller screw drive and hollow cooling technology (optional)

- Effectively inhibit the thermal elongation of the roller lead rod to ensure stable and long-term processing accuracy

- Adopt innovative nut rotary drive screw drive technology to effectively reduce load inertia and achieve higher positioning accuracy and dynamic response

+ Geared A/C turntable

- DIN5 imported precision grinding gear

- AFMING’s patented anti-backlash technology ensures zero clearance, high efficiency and ultra-high rigidity of precise gear transmission

+ GTCP high precision compensation package

- Through teaching model and related software, the linear errors of linear axis, vertical errors, rotation axis inclination and shifting errors generated during machine tool manufacturing and assembly are compensated, greatly improving the machining accuracy of machine tools

- It is embedded in the RTCP measurement cycle of the machine tool, easy to operate and friendly to the interface. Customers can operate by themselves after training

- Compared with the high cost instrument and operation time required for conventional space compensation, this compensation package has better precision performance and better operation convenience.

+ Standard linear grating ruler and circular grating

+ Automatic Tool measuring device (optional)

+ Oil-cooled, water-cooled controller

+ Other sophisticated measures

- All parts are precisely manufactured and tested, carefully adjusted and strictly assembled

- RTCP calibration

- Scraping technology

- Constant temperature workshop

Convenience of Operation

Ergonomically designed to achieve extraordinary processing proximity and visibility for an unparalleled and convenient operating experience.

1450mm operating height is very easy to manual operation.

Using the same keyboard form as the PC,the reply improves the convenience of work

19 “ink display

180° degree angle

1450 “mm screen center height

+ Crown-type bed structure for optimal processing area proximity

- The closest distance between the protective door and the spindle is only 390mm, and manual tool change or maintenance becomes within reach

- The protective door is integrated with the machine ceiling to facilitate the free lifting of the workpiece The maximum opening distance of the protective door is 1050mm, with spacious processing space and unobstructed visibility

+ Standard with 46 chain knife library tool to tool change time 12s

+ The number of props is standard 48T, optional 60T, to expand the processing flexibility

+ The processing area is protected by stainless steel plate, which has stronger anti-scratch and easy to clean, and the spraying device of the wall can be optional

+ The base of the chip removal system is designed with a large 45° slope to facilitate the removal of iron chips

- The chip removal rod is located under the rotary table, with a large diameter chip removal port, the chip removal is more smooth

- The A/C turntable can be turned over to dump most of the cutting waste into the lower chip discharge channel

+ Contact/laser tool setter for smarter and easier production (optional)

+ Five-axis Rotation Center Calibration (RTCP)

+ Equipped with up to 16 punching/ blowing combined ring punching nozzle, to meet the multi-dimensional water or air punching in multi-sided processing

5-axis CNC Machine Center GMU-800/900 Application

GMU-800/900 is the best option for heavy cutting.

Application area | +automotive industry +Civil aviation industry +industrial equipment +Mold industry

GMU800/900 5-axis CNC Machine Center Main Specifications

| Item | Unit | GMU-800 | GMU-900 | |

| Worktable | X/Y/Z axis travel | mm | 850/950/550 | 900/1050/600 (Y-axis travel includes 100 tool change travel) |

| A/C axis travel | Degree | ±120/360 | ±120/360 | |

| Distance from spindle nose to table surface (when A-axis is at 0) |

mm | 180-730 | 180-780 | |

| Table size/Maximum load | Mm/kg | Φ800/1000 | Φ800/1000 | |

| Spindle | Spindle maximum speed/taper shank | rpm | 15000/HSK-A63 | 18000/HSK-A63 |

| Spindle power (S1/S6-40%) |

kW | 18/22 | 30/37.5 | |

| Torque (S6-40%) | N.m | 57/70 | 105/130.6 | |

| Feed system | Rapid displacement of X/Y/Z | m/min | 32/32/32 | 40/40/40 |

| Maximum cutting feed rate | m/min | 20 | 20 | |

| A/C axis rapid feed rate | RPM/min | 20/30 | 20/30 | |

| Positioning accuracy (ISO 10791-4:1998) | X axis | mm | 0.007 | 0.007 |

| Y axis | mm | 0.007 | 0.007 | |

| Z axis | mm | 0.006 | 0.006 | |

| A axis | ARC” | 6 | 6 | |

| C axis | ARC” | 6 | 6 | |

| Repeat positioning accuracy (ISO 10791-4:1998) | X axis | Mm | 0.004 | 0.004 |

| Y axis | Mm | 0.004 | 0.004 | |

| Z axis | Mm | 0.004 | 0.004 | |

| A axis | ARC” | 4 | 4 | |

| C axis | ARC” | 4 | 4 | |

| Auto tool change system | Number of tools | Pcs | 48T | 48T |

| Tool change time (knife-knife) |

sec | 12 | 12 | |

| Tool max.length | mm | 300 | 380 | |

| Maximum tool diameter/no tool adjacent | mm | Φ75/Φ125 | Φ75/Φ125 | |

| Tool maximum weight | kg | 8 | 8 | |

| Dimensions | Overall height | mm | 3570 | 3740 |

| Floor space (length×width) |

mm² | 5200 x 3820 | 5000 x 4250 | |

| Machine net weight | kg | 17000 | 17000 | |

| Electricity demand | kw | 60 | 60 |

Standard configuration

| NO. | GMU800 | Standard configuration | No. | GMU900 | Standard configuration |

| 1 | System | Heidenhain iTNC 640 | 1 | System | Heidenhain iTNC 640 |

| 2 | Sheet metal | Capped full enclosure body sheet metal (include water tank) | 2 | Sheet metal | Fully enclosed uncapped fuselage sheet metal |

| 3 | Spindle | AFMING D1(HSK-A63/15,000rpm) | 3 | Spindle | HSK-A63/18000RPM AFMING Electric Spindle |

| 4 | A/C cradle turntable | Gear rotaton structure (imported DIN5 grade grinding gear) | 4 | A/C cradle turntable | Gear rotation structure (imported DIN5 grade grinding gear) |

| 5 | Spindle cooler | Oil cooler | 5 | Spindle cooler | Water cooler |

| 6 | Tool setter | Marposs contact | 6 | Tool setting instrument | Marposs Contact |

| 7 | Three-axis linear grating | Heidenhain | 7 | Three-axis linear encoder | Heidenhain |

| 8 | AC axis grating | Heidenhain | 8 | AC axis circular grating | Heidenhain |

| 9 | Tool magazine | HSK-A63-48T horizontal tool magazine | 9 | Tool magazine | HSK-A63-48T Flat tool magazine |

| 10 | Chip removal system | Scraper Type Chip Conveyor | 10 | Chip conveyor system | Scraper Type Chip Conveyor |

| 11 | Guide | 45 roller guide Xand Y,35 roller guide Z | 11 | Guides | X-axis 45 roller guides,Y-axis 45 roller guides,Z-axis 45 roller guides |

| 12 | Screw | X-axis R40x16,Y-axis R50x16,Z-axis R40x16 | 12 | Screw | X axis R40x20,Y axis R50x20,Z axis R40x20 |

| 13 | Electric box constant temperature system | Air Conditioning | 13 | Electric box constant temperature system | Air-conditioned (Tongfei) |

| 14 | Pneumatic system | Japan SMC | 14 | Pneumatic system | Japan SMC |

| 15 | Hydraulic station | Taiwan 7Ocean | 15 | Hydraulic station | Taiwan 7 Ocean |

| 16 | Automatic lubricating device | Grease type (China) | 16 | Automatic lubrication device | Grease(China Liubian) |

| 17 | Processing area cleaning | Air gun,water gun for cleaning | 17 | Processing area cleaning | Air guns,water guns for cleaning |

| 18 | Working lamp | LED lighting | 18 | Working lamp | LED Light |

| 19 | Warning light | Three-color warning light | 19 | Warning Light | Tri-color warning light |

| 20 | Tool box and anchor screws | Tool box and anchor screws | 20 | Tool box and anchor screws | Toolbox and anchor screws |

| 21 | Five-axis centering kit | (With 3D probe)Heidenhain | 21 | Five-axis center correction package | (With 3D probe)Heidenhain |

| 22 | Automatic ceiling &oil mist collecton components | GMU800-QS-1500(Qiushan) | 22 | Automatic ceiling &oil mist collection components | QS-1500(Qiushan) |

| 23 | Safety door lock | GMU800-Shansen safety door lock | 23 | Safety door lock | Shansen safety door lock |

Optional configuration

| NO. | GMU800 | Optional configuration | NO. | GMU900 | Optional configuration |

| 1 | Rapid displacement of X/Y/Z axis | 40/40/40 | 1 | HSK-A6315000rpm Kessler electric spindle | Power:30/46kw Torque:130/200Nm |

| 2 | HSK-A6318000rpm AFMING electric spindle | Power:30/37.5kw Torque:105/130.6Nm | 2 | HSK-A6320000rpm Kessler electric spindle | Power:25/40kw Torque:87/135Nm |

| 3 | HSK-A6315000rpm OMLAT electric spindle | Power:30/40kw Torque:133/178Nm | 3 | HSK-A6315000rpm OMLAT electric spindle | Power:30/40kw Torque:133/178Nm |

| 4 | HSK-A63-60T tool magazine | HSKA63-60T Including selection institutions | 4 | HSK-A63-60T tool magazine | HSKA63-60T Including selection institutions |

| 5 | Blum laser tool setter | GMU800-182000 | 5 | Blum laser tool setter | GMU700-182000 |

| 6 | Workbench pneumatic tooling port pipeline components | GMU800-Workbench pneumatic tooling port pipeline components | 6 | 4 gas 2 airtight_worktable fixture port components | GMU900-430002 |

| 7 | CTS 30bar spindle center water outlet | 7 | Workbench pneumatic tooling port pipeline components | GMU800-Workbench pneumatic tooling port pipeline components | |

| 8 | CTS 50bar spindle center water outlet | 8 | CTS 30bar spindle center water outlet | ||

| 9 | CTS 70bar spindle center water outlet | 9 | CTS 50bar spindle center water outlet | ||

| 10 | Automatic door | GMU800EVO-Self departmental components | 10 | CTS 70bar spindle center water outlet | |

| 11 | Paper tape filtering | Paper tape fitering component | 11 | Automatic door | GMU800EVO-Self departmental components |

| 12 | Paper tape filtering | Paper tape fitering component | |||

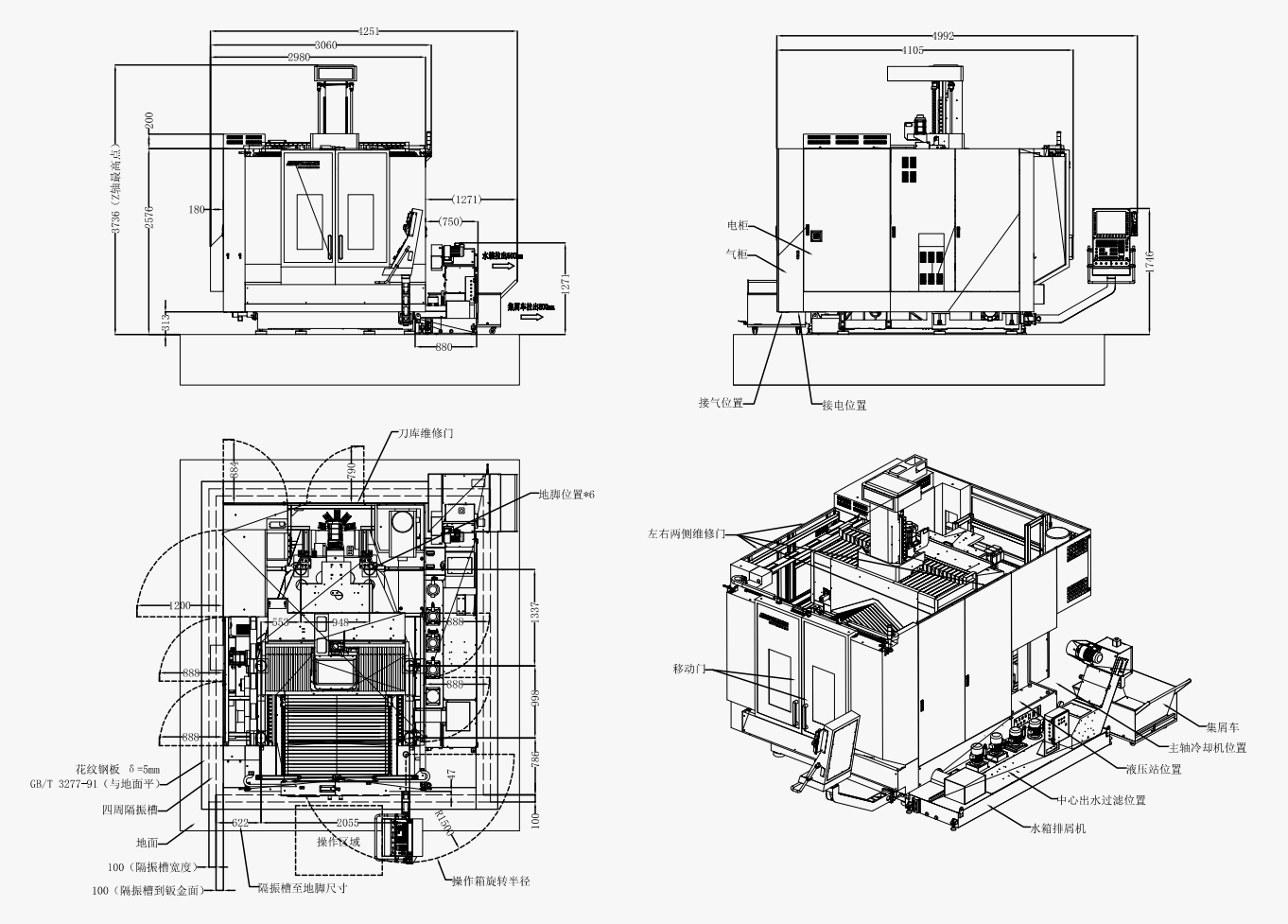

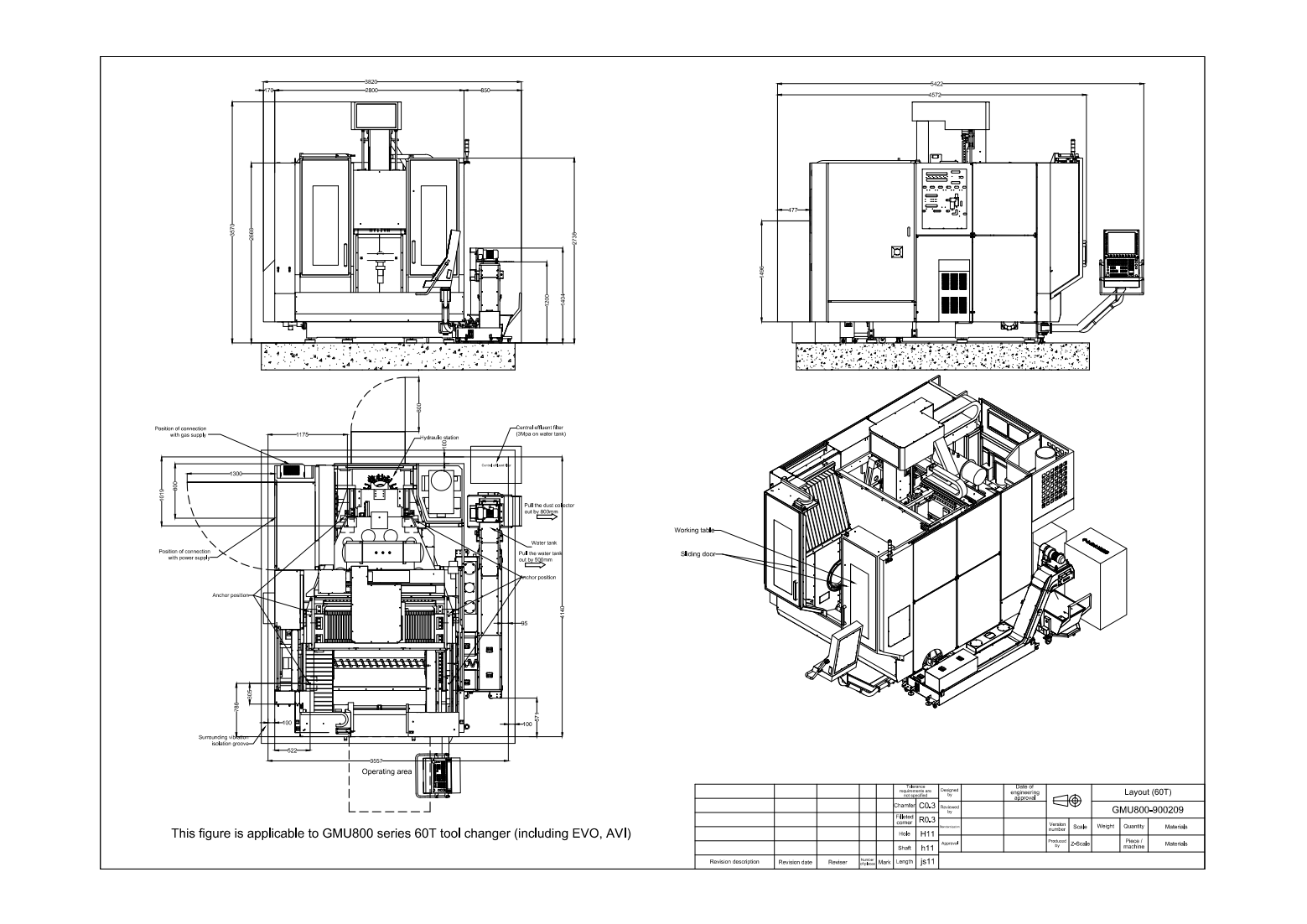

Machine Layout diagram (GMU-900)

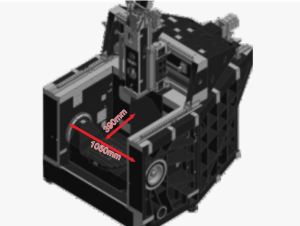

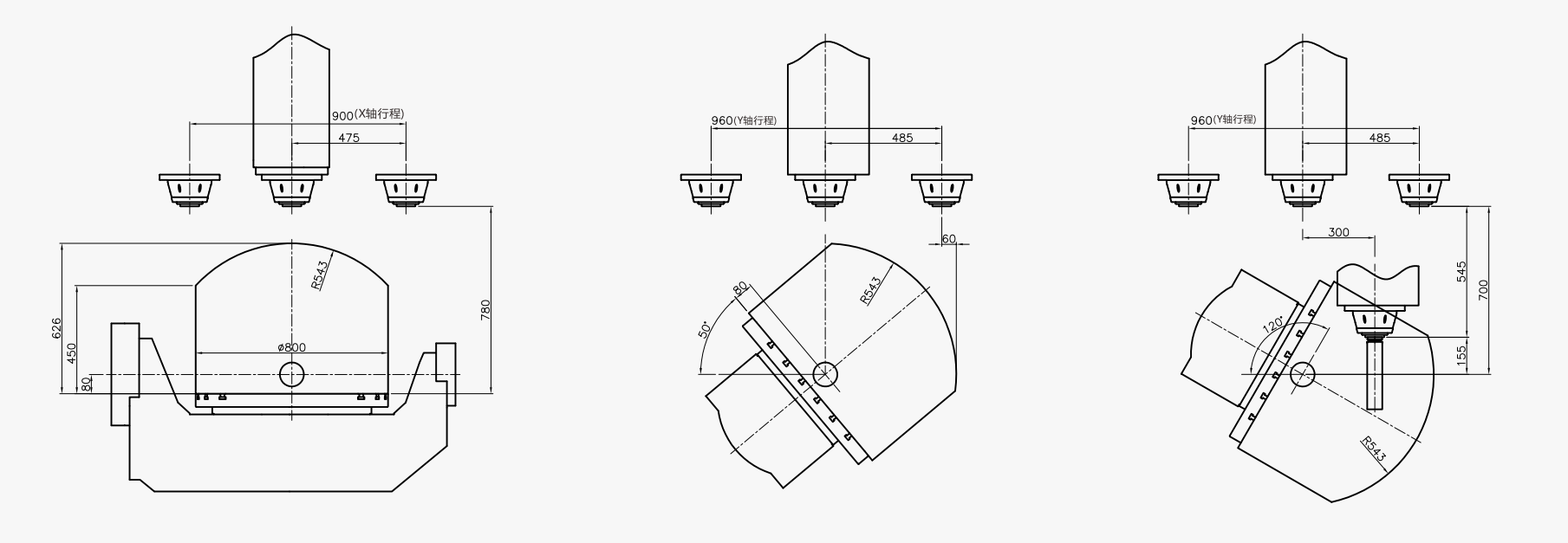

Machining interference pattern(GMU-900)

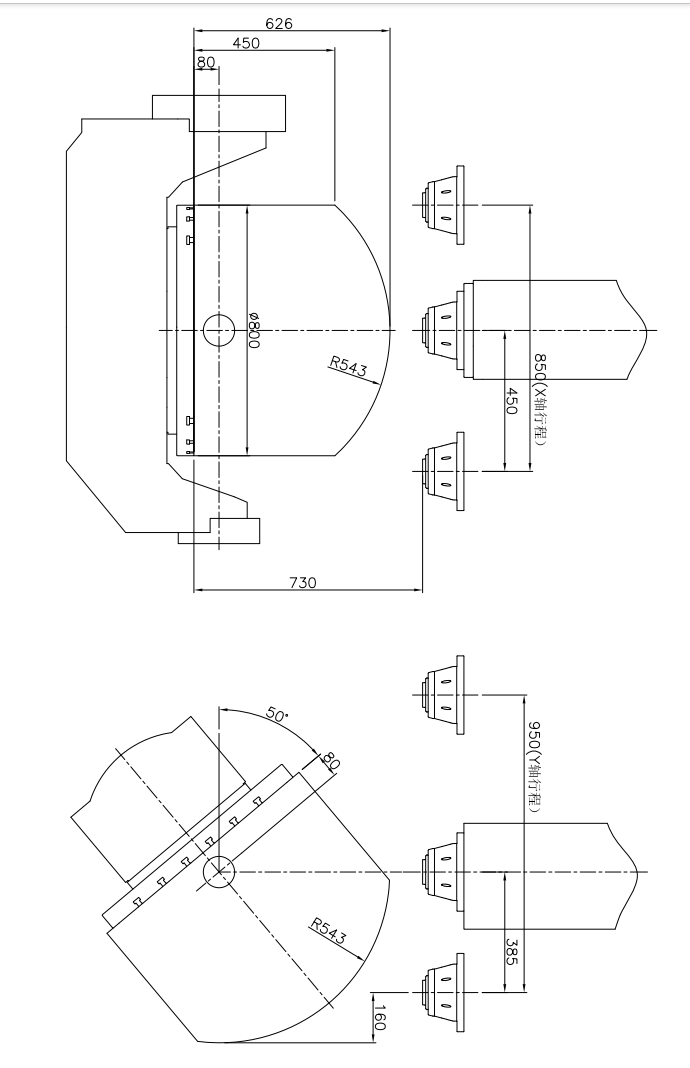

AFMING 5-axis CNC Machine Center Layout Diagram(GMU-800)

Machine interference pattern(GMU-800)