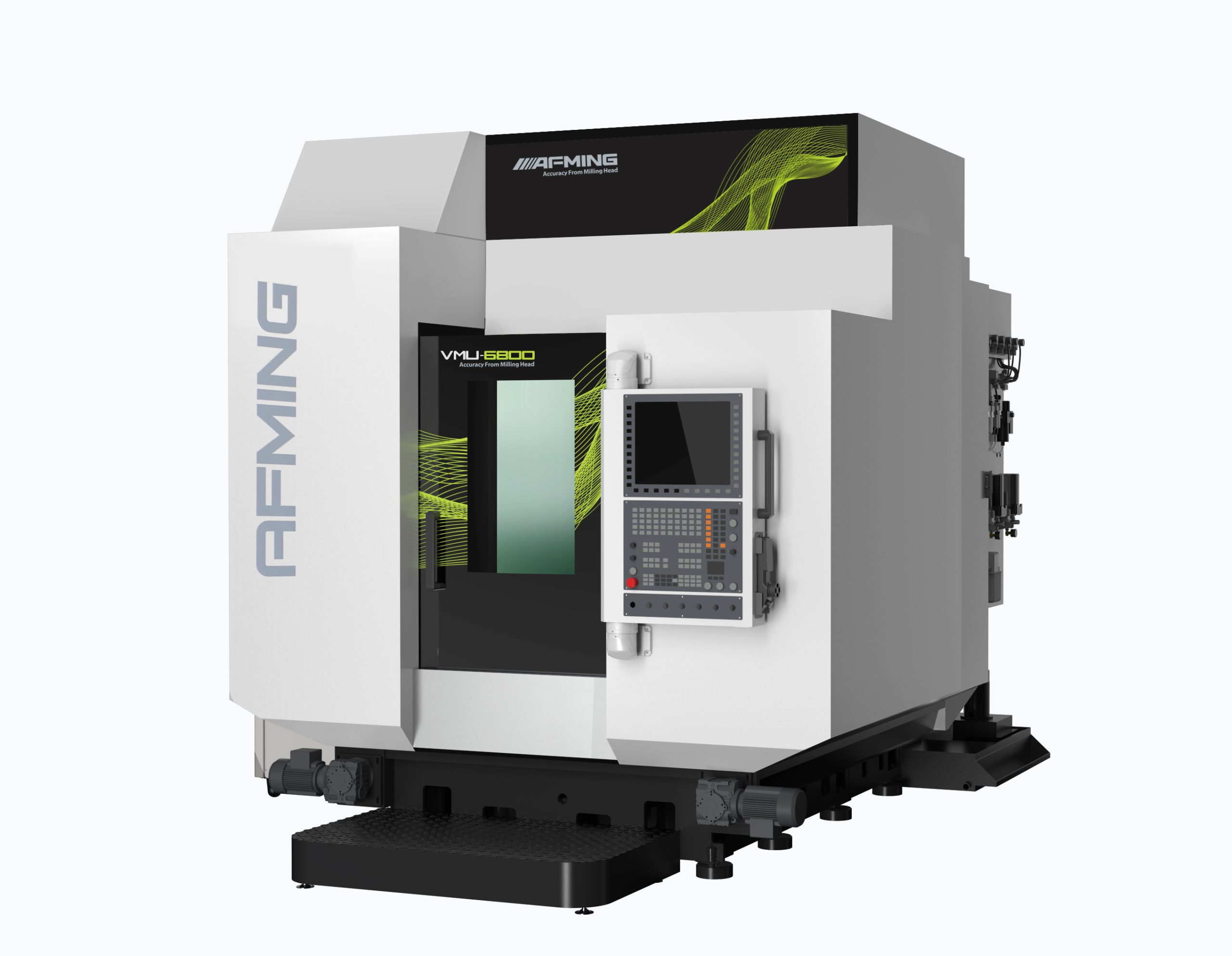

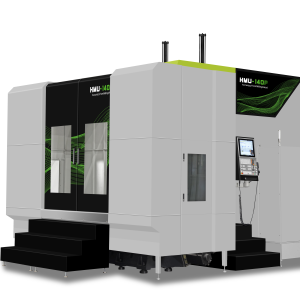

Introduction of 5 axis Vertical Machine Center VMU-6800

VMU-6800 adopts a moving column vertical structure, the bed is integral, and the material is high-standard cast iron. the 5 axis vertical machine center has the performance of high speed, high precision and high added value, and it is widely used in multi-faceted five-axis processing of complex parts in medium-sized molds, auto parts and other related industries. The A-axis of the cradle turntable adopts precision anti-backlash gear transmission, which has higher output torque and stronger torsional rigidity than conventional torque motor transmission. When the load changes, the stability of the electromechanical servo system is superior; the C-axis of VMU-6800 adopts torque motor direct drive, with excellent dynamic response and rotation accuracy.

Why Choose the Vertical Machine Center VMU-6800?

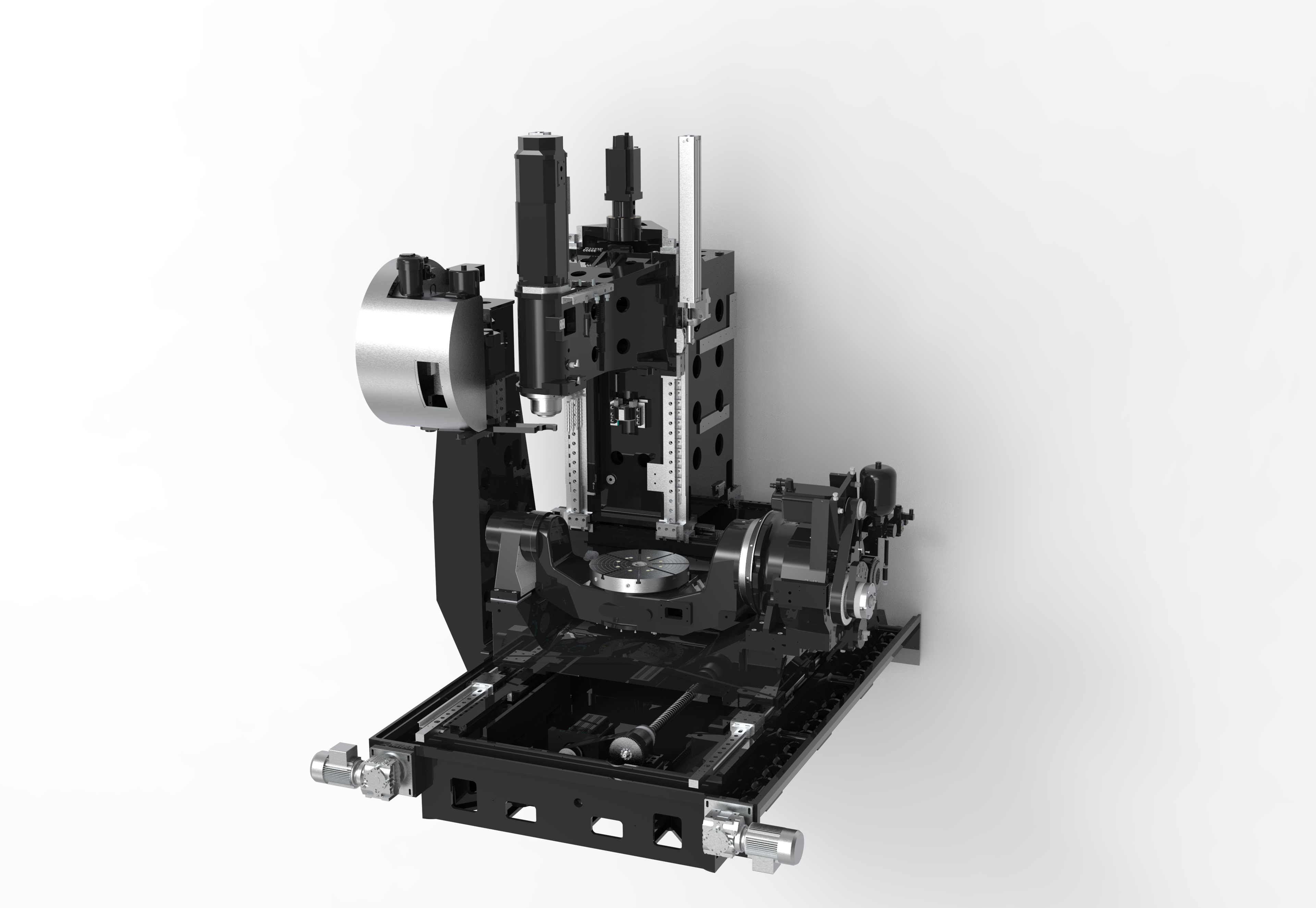

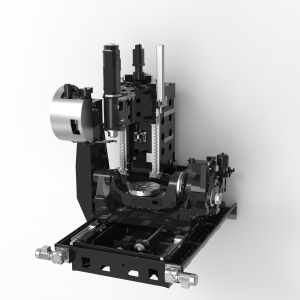

1, High-rigidity Bed Structure

VMU6800 adopts the moving column vertical structure design is stable and reliable, the base supports the cradle turntable with a long span, and the X/Y/Z axis is supported by 45mm roller guide rail, achieving excellent dynamic performance and accuracy preservation.

Machine Frame Highlights

- VMU6800 vertical machine center adopts moving column vertical structure design is stable and reliable.

- The diameter of the working table is 500mm and the maximum clamping is 800mm

- Rapid displacement of X/Y/Z axis up to 36m/ min.

- The maximum cutting feed rate is 20m/ min.

- X/Y/Z axis for high response ball screw drive, screw pre-stretching effective suppression of thermal elongation, high accuracy and stability.

- Axis A is DIN5 high precision gear drive, static torque 3500Nm

- Axis C is DD motor direct drive, the speed is 80rpm.

- Optional Heidehan linear grating ruler, X/Y/Z axis positioning accuracy 0.008/0.008/0.008mm, A/C axis standard with Heidehan, circular grating positioning accuracy 8 Angle seconds.

- Tool measuring device (optional).

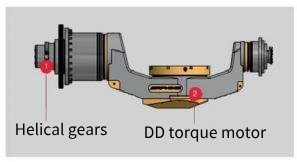

2, Perfect Merge of High Rigidity & High Dynamics

VMU6800 The A-axis of the cradle turntable adopts precision anti-backlash gear transmission, which has higher output torque and stronger torsional rigidity than conventional torque motor transmission. When the load changes, the stability of the electromechanical servo system is superior; the C-axis adopts torque motor direct drive, with excellent dynamic response and rotation accuracy.

GTRT Gear Driven Turntable of VMU-6800 Vertical 5 axis Machine Center

- A-axis: servo motor + helical gear (patented double-stage backlash elimination technology)

- C-axis: torque motor (high-speed response)

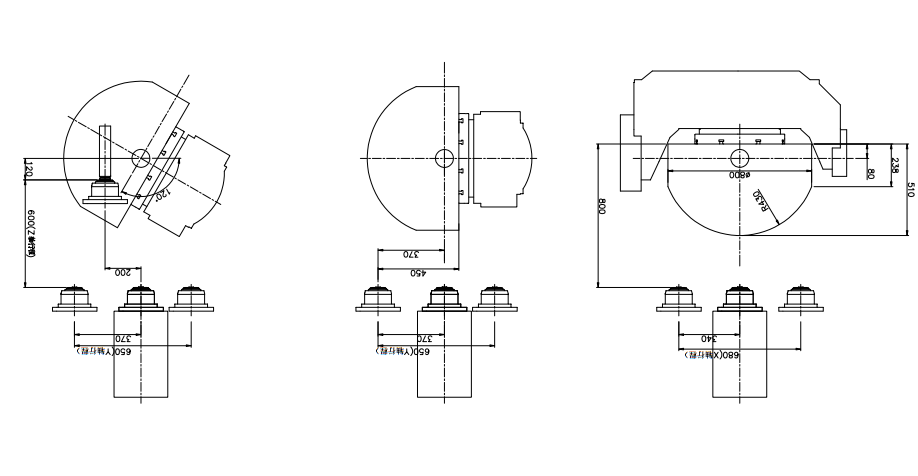

- Stroke (A/C): ±120°/360°

- Maximum speed (A/C): 20/80 rpm

- Positioning/repeatability (A/C): 8“/5”

- Static torque (A): 3500 N.m

- Braking torque (C): 1200 N.m

- Rated torque (A/C): 2000/430 N.m

- Load capacity: 300 kg

3, Super Power Mechanical Spindle

Equipped with 12000 spindle options, fully consider parts processing, mold processing and other special processing conditions, to provide customized spindle solutions, expand the processing range, improve processing efficiency.

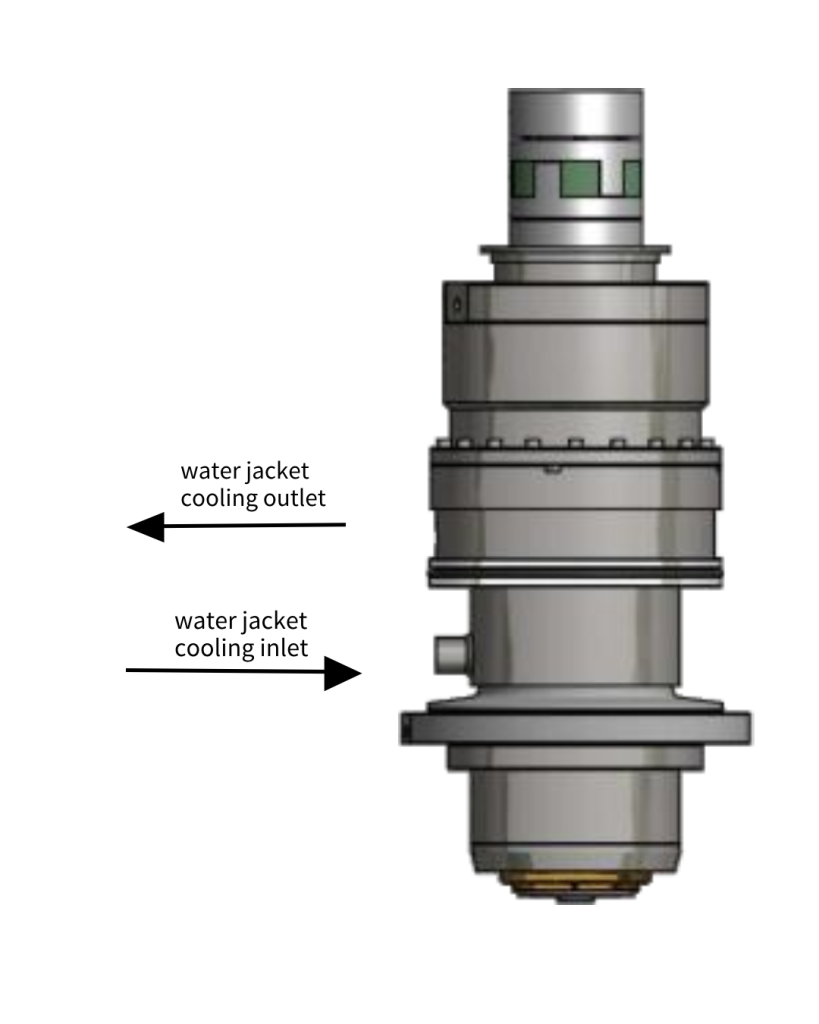

Spindle double jacket double cooling system

◆ Double water jacket design, internal and external water jacket combination, so that the mandrel and bearing get double cooling, effectively maintain the spindle temperature stability

◆ With the well-designed circulating cooling runner, both the mandrel and the bearing are well cooled, which provides a strong guarantee for the working performance, stability, processing accuracy and life of the spindle for long-term high-speed operation.

Up to 15000rpm Directly coupled spindle is suitable for high-speed machining of high-finish surfaces

Mechanical Spindle Features

- High elastic spindle: The spindle requires only 6 large disc springs.

- Long spindle life: Super long life, with a lifespan of over 2 million times.

- Spindle tool release reverse lock mechanism:The cutting force is directly applied to the spindle shaft, and the spindle bearings are not subjected to force, which effectively extends the life of the spindle bearings.

- High rigidity spindle: The bearing span has been iterated to optimize stiffness, ensuring the spindle has the best heavy cutting performance.

- Spindle double-layer cooling system: The double water jacket design and the combination of inner and outer water jackets allow the spindle and bearings to be doubly cooled, effectively maintaining the temperature rise of the spindle stable.

- DIN Low carbon alloy steel: The spindle material is DIN low carbon alloy steel, carburized and quenched, and precision ground.

4, Using finite element analysis and dynamic optimization

Dynamics optimization is performed through FEA during design to achieve the best match of the structural qual ity, stiffness, and damping of the entire machine, thereby reducing the cost of the tool. The cross dynamic compl iance between the tip and the workpiece increases the regenerative chatter l imit during rough machining, increases the cutting amount during rough machining, and achieves the purpose of efficient cutting. At the same time, because the relative ampl itude between the tool tip and the workpiece is reduced, the surface finish during processing is improved, the vibration speed of the tool tip is reduced, and tool wear is reduced.

- + Dynamic optimization through FEA, effectively improve the anti-vibration of the whole machine

- +Accurately calculate the optimal dynamic rigidity under actual working conditions

- +Improve the natural frequency and cutoff frequency of the feed drive system, effectively reduce the positioning time and the lag of the feed system to achieve high-response dynamic performance and high-speed machining profile accuracy

VMU-6800 Technical Parameter

| Item | Unit | VMU-6800 | |

| Systems (Control Units) |

System | Heidenhain iTNC 620 | |

| Worktable | X/Y/Z axis travel | mm | 680/600/600 |

| A/C axis travel | degree | +-120/360(unlimited) | |

| Distance from worktable to spindle nose |

mm | 200-800 | |

| table size/maximum load capacity | Mm/kg | φ500/300(round worktable) | |

| Spindle | Max.spindle speed/tapered shank | Rpm/holders | 15000/HSK-A63 |

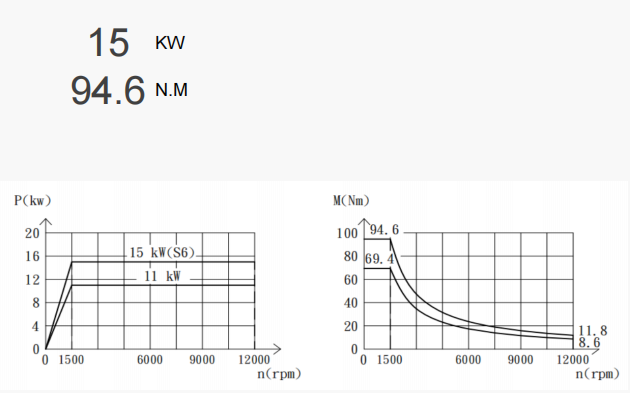

| Spindle power(S1/S6-25%) | kW | 11/15 | |

| Spindle torque(S1/S6-25%) | N.m | 69.4/94.6 | |

| Feedng System | X/Y/Z axis rapid displacement | m/min | 36/36/36 |

| Max.cutting feedrate | m/min | 20 | |

| A/C axis fast feedrate | rpm | 20/80 | |

| Positioning accuracy ISO 10791-4:1998 | X/Y/Z | mm | 0.008/0.008/0008 |

| A/C | ARCSEC | 8/8 | |

| Repetitive Positioning Accuracy ISO 10791-4:1998 | X/Y/Z | mm | 0.006/0.006/0.006 |

| A/C | ARCSEC | 5/5 | |

| Automatic Tool Change System | Number of tools | pcs | 30T |

| Tool change time (tool-to-tool) | sec | 2.5(Varies depending on factors such as spindle unclamping) |

|

| Max.tool length | mm | 300 | |

| Max.tool diameter/adjacent no tool | mm | φ75/φ150 | |

| Max.tool weight | kg | 8 | |

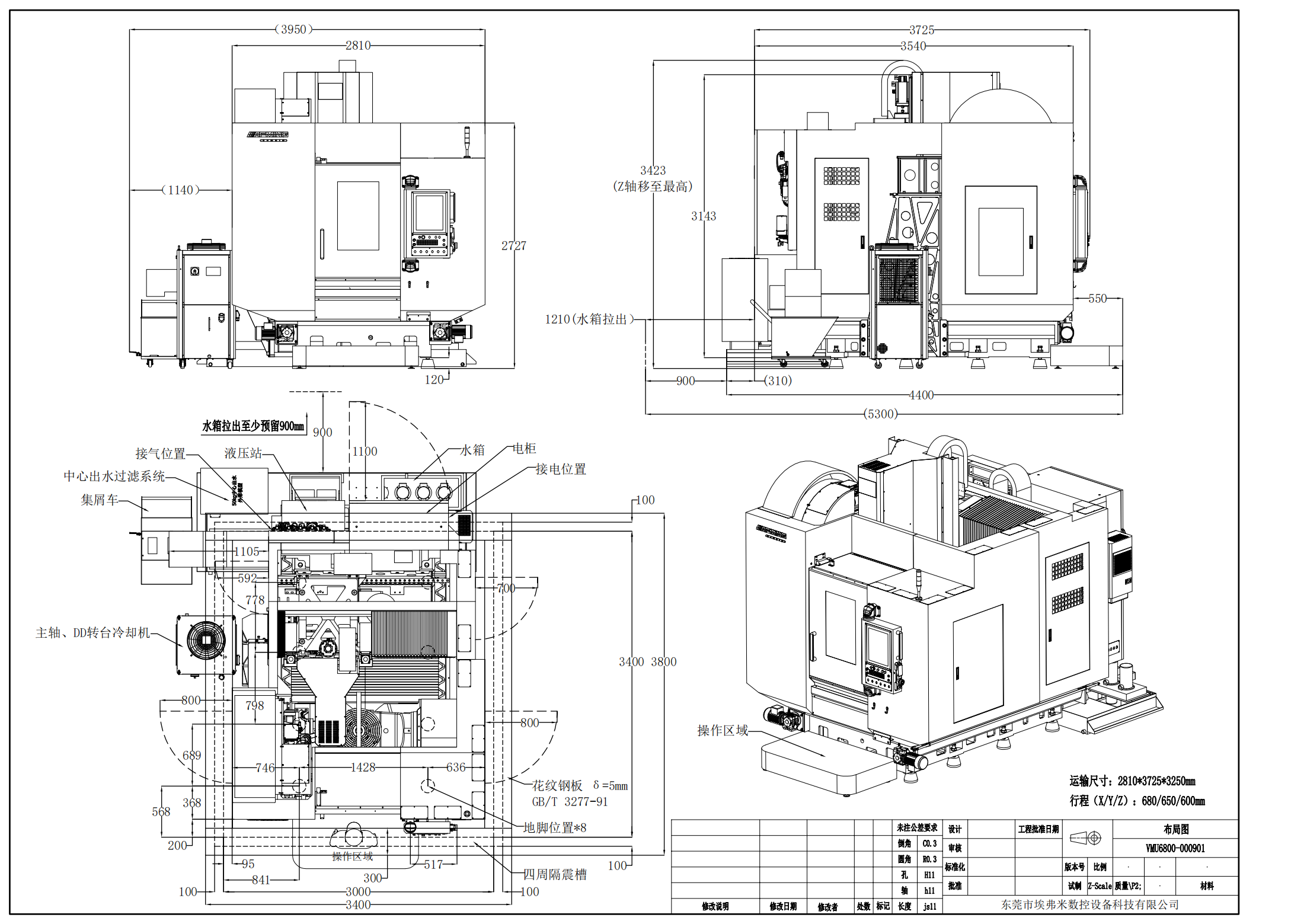

| Machine dimension | Total height of machine tool | mm | 3500 |

| Floor space(L×W) | mm² | 3700 x 4400 (with chip conveyor) | |

| Net weight of machine tool | kg | 13000 | |

| Power requirement | kw | 45 | |

VMU-6800 Vertical Machine Center Standard/Optional

| No. | Standard configuration | Options | Specification | |

| 1 | System | Heidenhain iTNC 620 | HSK-A63 12000rpm AFMING direct spindle | Power:11/15kw Torque:69.4/94.6Nm |

| 2 | Cover | Full enclosure type cover(including water tank) | Hexagon laser tool setter | VMU6800-180003 |

| 3 | Spindle | HSK-A63 15000rpm D1 direct spindle | Blum laser tool setter | VMU6800-180003 |

| 4 | A/C Cradle turntable | A axis gear rotation structure (imported DIN5 grinding gear) C axis: DD turntable motor direct drive (YRT bearing) | Safety door lock | VMU6800-Shansen safety door lock |

| 5 | Spindle coolant | Oil coolant | CTS 30bar spindle center water outlet | |

| 6 | Tool setting | Marposs contact | CTS 50bar spindle center water outlet | |

| 7 | Three axis grating ruler | Heidenhain | CTS 70bar spindle center water outlet | |

| 8 | AC axis circle grating | Heidenhain | Oil mist collector | VMU6800-QS-750(Qiu shan Machinery) |

| 9 | Tool magazine | HSK-A63-30T Arm type tool magazine | Roof sheet metal | VMU6800-Roof sheet metal components |

| 10 | Chip conveyor | Chain plate chip conveyor | System Function Options | Five axis collision prevention |

| 11 | Guide rail | X-axis 45 roller guide, Y-axis 45 roller guide, Z-axis 45 roller guide | ||

| 12 | Screws | X axis R50x12, Y axis R50x20, Z axisR40x12 | ||

| 13 | Electric box constant temperature system |

Air conditioner (Tongfei) | ||

| 14 | Pneumatic system | Taiwan Airtac | ||

| 15 | Hydraulic pressure station | Taiwan Qiyang | ||

| 16 | lubrication system | Grease type(Liubian, China) | ||

| 17 | Machining area cleaning | Air gun, water gun for cleaning | ||

| 18 | Working lights | LED lighting | ||

| 19 | Warning lights | Three color warning light | ||

| 20 | Tool box and ground screw | Toolbox and ground screws | ||

| 21 | Five-axis center alignment kit | (with 3D probe) Heidenhain | ||

Machine arrangement diagram

Machining interferogram

VMU6800 five axis vertical machine center application

- Positioned in die-casting automotive parts processing

- Through the independently designed cradle turntable technology, the machine tool has achieved high rigidity and stability

- Suitable for high-volume and multi- variety parts processing, focusing on optimizing processing technology, improving production line flexibility, and

achieving a smooth processing process.