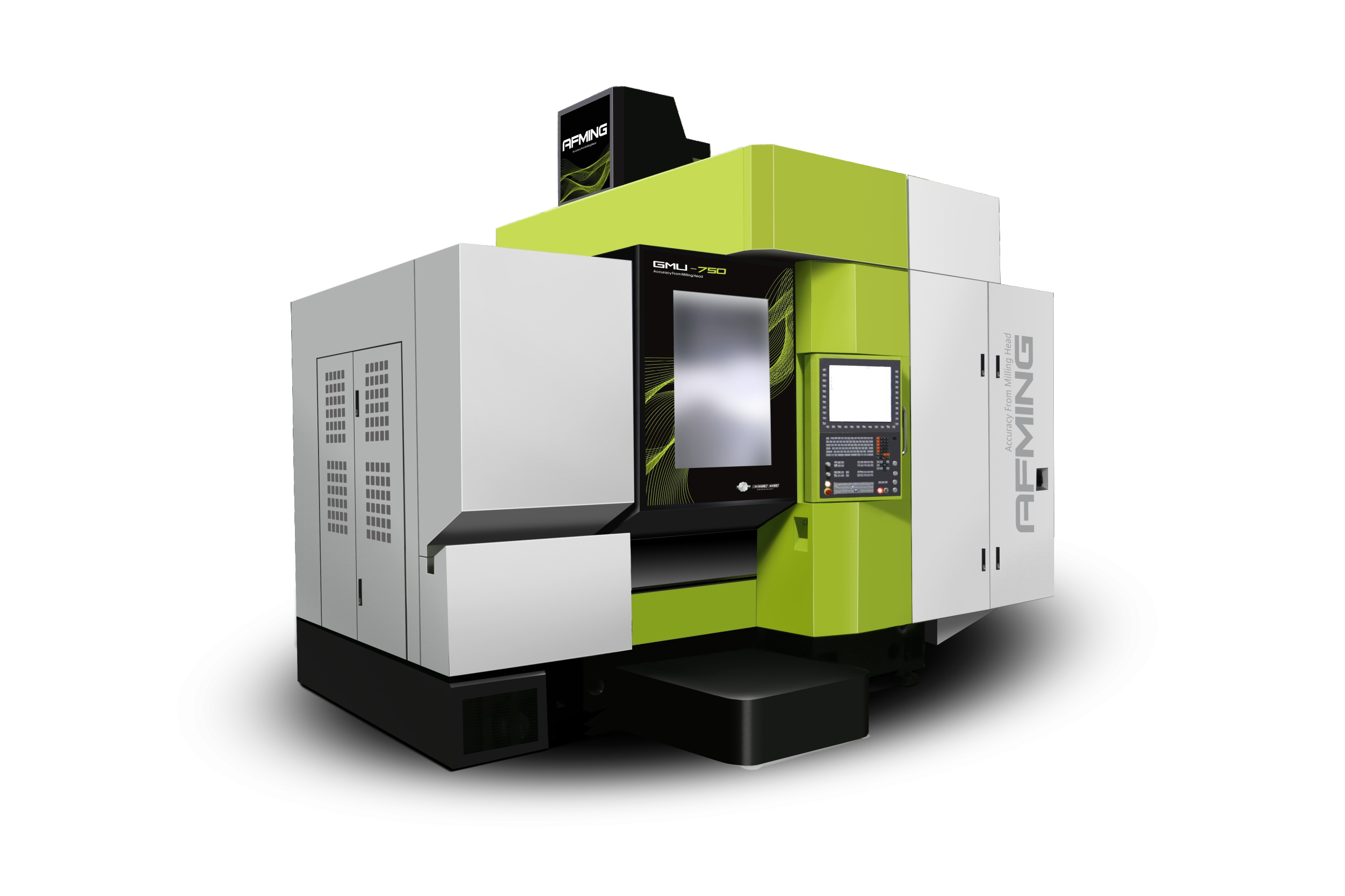

How about our GMU750 5-axis Fixed-beam Gantry CNC Machine Center ?

GMU-750 5 axis machine center upholds the strong rigidity of the fixed beam gantry structure, carrying the technology of mechanical transmission turntable developed by AFMing. It combines with the patent of gear backlash reduction and the torsion damping mechanism of turntable, and has the support through the research and development technology of self-developed spindle, which makes GMU750 to achieve efficient and accurate simultaneous processing.

| NAS Part Accuracy Results | ||

| NAS | Circular accuracy | 0.012 mm |

| Roundness | <0.006 mm | |

| Planeness | <0.01 mm (Φ 80/300 x 400 mm) | |

| Surface finish | 0.04 mm Pa (Φ 80/300 x 400 mm) | |

| *Results may vary from catalogue in different measurement environment and working conditions. | ||

| GMU-750 | ||

| X/Y Positioning /Repeat positioning | 0.008/0.005 mm | |

| Z Positioning /Repeat positioning | 0.007/0.004 mm | |

| AC Positioning /Repeat positioning | 6/4ARCSEC | |

| *Per ISO 10791-4:1998 | ||

5-axis Machine Center Advantage:

The GMU750 is a effective and accurate simultaneous five axis machine center, all thanks to rigidity from bridge-type frame, the AFMING unique gear drive turn table, patented backlash elimination technology, turntable damping mechanism and strong spindles.

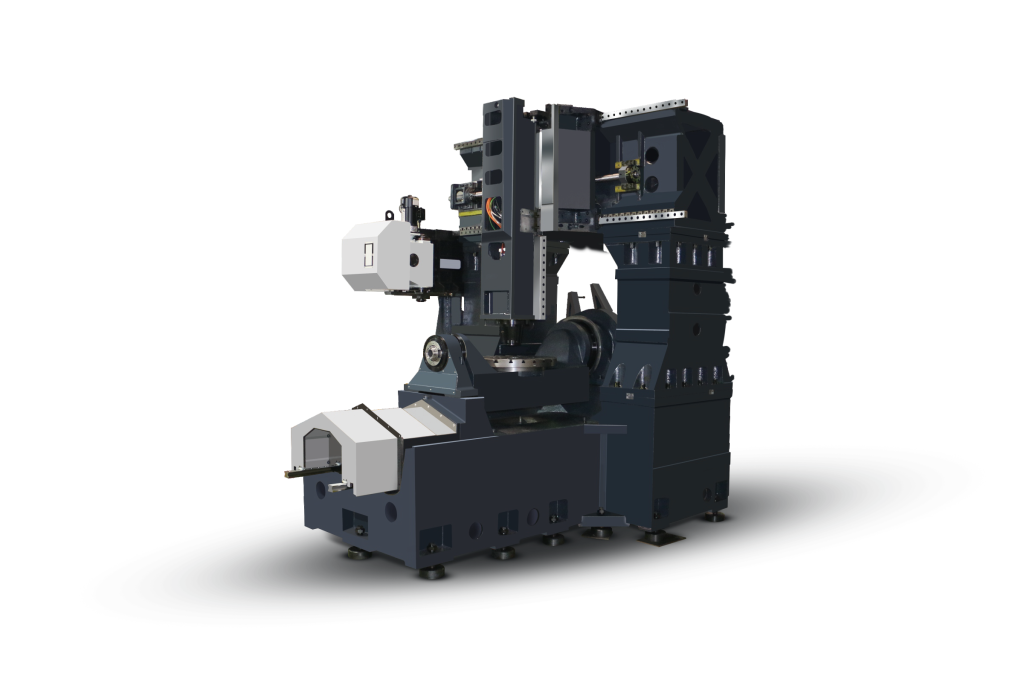

1, Fixed-beam gantry frame

The design adopts fixed beam gantry bed structure to ensure high rigidity, high precision and high efficiency and stability of bed structure.

- Weighing optimization of moving parts, perfect dynamic performance

- Z axis rigidity and dynamic property 30% higher than peers

- Extra large support for better stability

- One-piece structure, lighter for higher rigidity

- FEA optimized frame and moving parts

- First natural frequency of 67 HZ, great vibration suppression

- 0.8 G acceleration for 3 axis

2, High response dynamic performance

GMU750 5 axis machine center adopts finite element analysis and dynamic optimization to improve the static and dynamic characteristics of each part of the machine to ensure the overall rigidity, stability and dynamic accuracy.

- Optimized stiffened structure, thermal symmetry and high rigidity.

- Perfect dynamic rigidity for excellent machining performance at heavy duty milling.

- Fine calculation of minimal cross compliance, improves the vibration limit for high speed and high precision machining.

- Higher mechanical intrinsic frequency and driving system cut-off frequency, improved KV value for positioning ring and reduced positioning time also feeding system lagging. High dynamic response and performance.

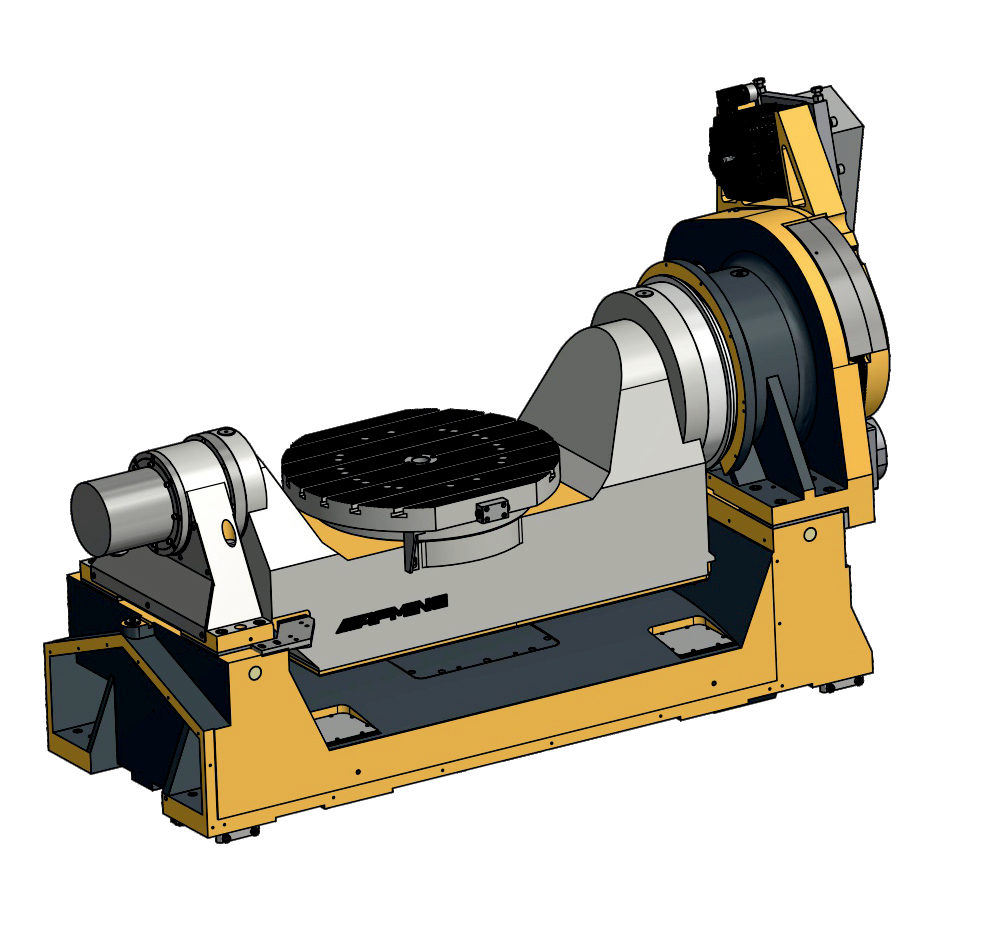

3, Strong turn table, high rigidity and precision

We own the design of this cradle turn table, featuring with our patented A/C axis double-pinion backlash elimination structure and torsional damper.

- GTRT transmission technology

- AFMING patent backlash elimination

- Double-end support, high rigidity, load and precision

- DIN 5 grade gear

- Good variety for materials including steel and titanium alloy

- All equipped with A/C axis HEIDENHAIN circular grating

- Easier cleaning and chip removal

- Innovative damper for cradle

GTRT turntable

A axis: Servo motor + dual-pinion backlash elimination + torsional damper

C axis: Servo motor + dual-pinion backlash elimination

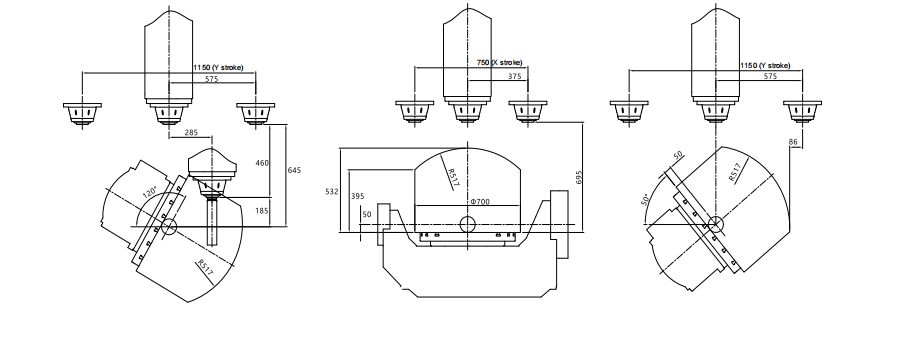

| Travel (A/C): | ±120°/360° |

| Max rpm (A/C): | 20/30 |

| Static torque (A/C): | 3,150/1,295 Nm |

| Accuracy (A/C): | 4″/4″ |

| Load: | 500 Kg |

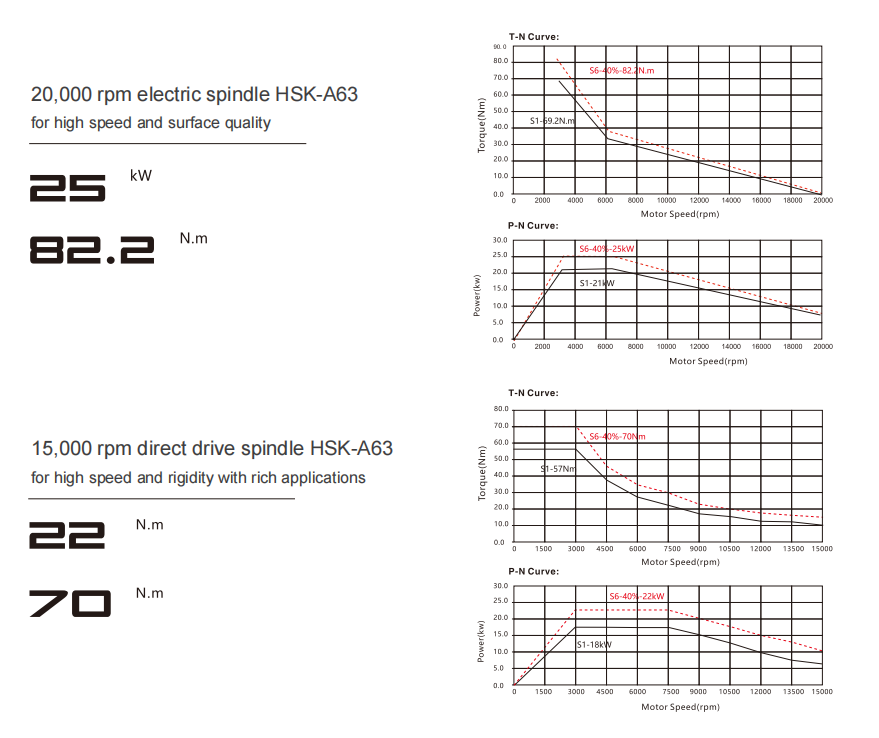

4, SUPERPOWER Electric Spindle

As the key of machining and critical component, AFMING spindle enjoys advanced technology and quick-and-easy maintenance, helping customer to optimize productivity.

- Front seal: slinger + labyrinth + airtight, prevent prevent contamination and guarantee spindle precision and lifetime.

- Hydraulic drive tool releasing cylinder, no load on bearing and improves its service time

- Spindle made of DIN low carbon steel alloy, carburized, quenched and precisely grind

- Optimized bearing arrangement for best rigidity and performance in heavy duty milling

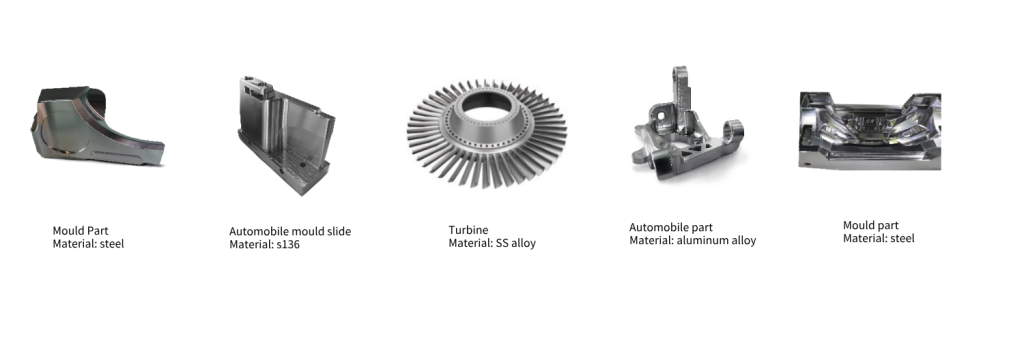

GMU750 Five-axis Machine Center Application:

Applications: + Automobile + Mold + Medical + Civil aviation

GMU-750/750D Technical specification

| Name | Unit | GMU-750 | GMU-750D |

| System | HEIDENHAIN-iTNC640 | HEIDENHAIN-iTNC640 | |

| XY/Z stroke | mm | 750/1150/550 | 750/1150/550 |

| A/C stroke | Degree | ±120/360 | ±120/360 |

| Distance from table to spindle nose (A axis at O degree) | mm | 130-680(direct drive) | 130-680 (direct drive) |

| Table size | mm | 中630 | φ700 |

| Maximum load capacity | kg | 500 | 400 |

| Spindle | |||

| Spindle (standard) | |||

| Spindle max rpm/tapered shank | rpm | 15000/HSK-A63 | 15000/HSK-A63 |

| Spindle power | kW | 22 | 22 |

| Torque | N.m | 70 | 70 |

| Feeding system | |||

| XM/Z-axis rapid displacement | m/min | 36/36/30 | 36/36/30 |

| Max.cutting feed rate | m/min | 20 | 20 |

| Acceleration | m/s2 | 0.8 | 0.8 |

| A/C axis rapid feed rate | RPM/min | 20/30 | 30/80(C-axis DDR) |

| Nominal torque A/C | N.m | 2080/990 | 2080/860 |

| Static torque AC | N.m | 3150/1295 | 3150/1570 |

| Brake torque A/C | N.m | 5000/0 | 5000/3500 |

| Postioning accurancy (ISO 10791-4:1998) | |||

| X/Y | mm | 0.008/0.008 | 0.008/0.008 |

| Z | mm | 0.007 | 0.007 |

| A/C | ARCSEC | 8/8 | 6/6 |

| Repeat positioning accurancy (ISO 10791-4:1998) | |||

| X/Y | mm | 0.005/0.005 | 0.005/0.005 |

| Z | mm | 0.004 | 0.004 |

| A/C | ARCSEC | 5/5 | 4/4 |

| Auto tool change system | |||

| Number of tools | Pcs | 30 T | 30 T |

| Tool-tool change time | sec | 2.5 S | 2.5 S |

| Tool max.length | mm | 300 | 300 |

| Tool max.diameter/no tool adjacent | mm | φ80/φ120 | φ80/φ120 |

| Tool max.weight | kg | 8 | 8 |

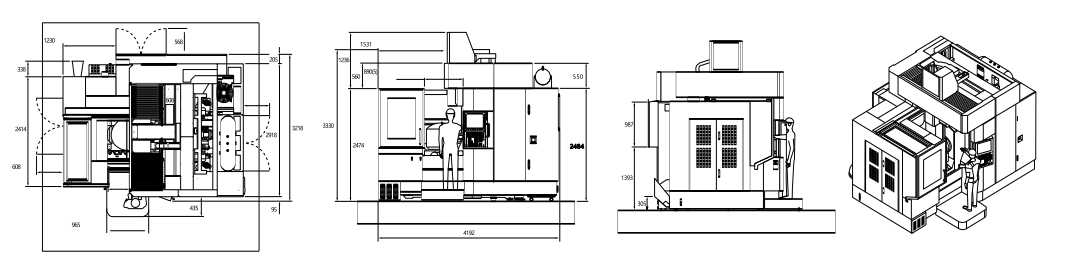

| Dimensions | |||

| Total height | mm | 3900 | 3900 |

| Floor space (length x width) | mm | 4570 X 4440 | 4570 X 4440 |

| Net weigh | kg | 16000 | 16000 |

| Power | kW | 60 | 60 |

Standard/Optional

| ● Standard O Optional * N/A | |||

| GMU-750 | GMU-750D | ||

| System | SIEMENS-ONE | ○ | ○ |

| HEIDENHAIN-iTNC640 | ● | ● | |

| HNC-848 | ○ | ○ | |

| Centering kit(with 3D probe &ball) | ○ | ○ | |

| Spindle | Anticolision function | ○ | ○ |

| 15000rpm spindle HSK-A63 | ● | ● | |

| 20000rpm spindle HSK-A63 | ○ | ○ | |

| Spindle cooler | ● | ● | |

| CTS system | ○ | ○ | |

| Spindle dust-proof air system | ● | ● | |

| Magazine | 24T disk | ● | ● |

| 30T disk | ○ | ○ | |

| 40T chain | ○ | ○ | |

| 60T chain | ○ | ○ | |

| Precision | Laser tool setter (auomatclengh&wer mesuring) | ○ | ○ |

| Contact tool setter | ○ | ○ | |

| X,Y,Zaxis grating | ○ | ○ | |

| A,C axis grating | ● | ● | |

| A axis brake | ● | ● | |

| C axis brake | ● | ● | |

| C axis DD torque motor | * | ● | |

| C axis DD torque motor with turning | * | * | |

| Chip System | Scraper chip conveyor | ● | ● |

| Chip collector | ● | ● | |

| Fluid gun | ● | ● | |

| Air gun | ● | ● | |

| Roof | ● | ● | |

| Full metal cover | ● | ● | |

| Fluid system | ● | ● | |

| Air gun at machining | ● | ● | |

| Oil mist collector | ○ | ○ | |

| Oilwater separator | ○ | ○ | |

| Safety system | Safety door switch | ○ | ○ |

| Lubrication | Automatic greasing | ● | ● |

| Electrical | Work lamp | ● | ● |

| Warning light | ● | ● | |

| Electric cab aircon | ● | ● | |

| Others | Tool box | ● | ● |

| Anchor screws | ● | ● | |

| Operation manual | ● | ● | |

Machine Layout diagram (GMU-750)